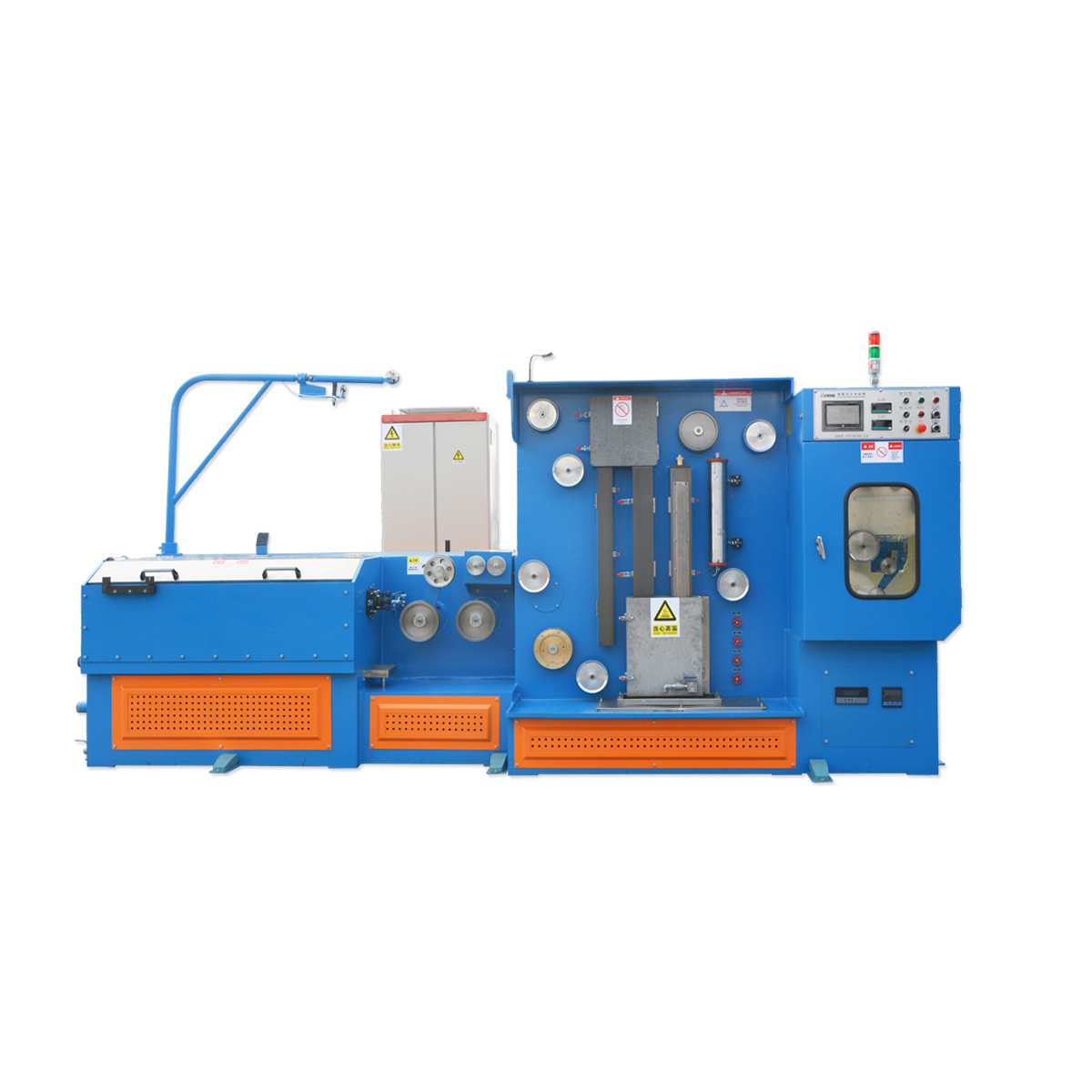

1. The tower wheels are designed with a double-layer arrangement, which efficiently saves space and optimizes the overall spatial layout of the equipment.

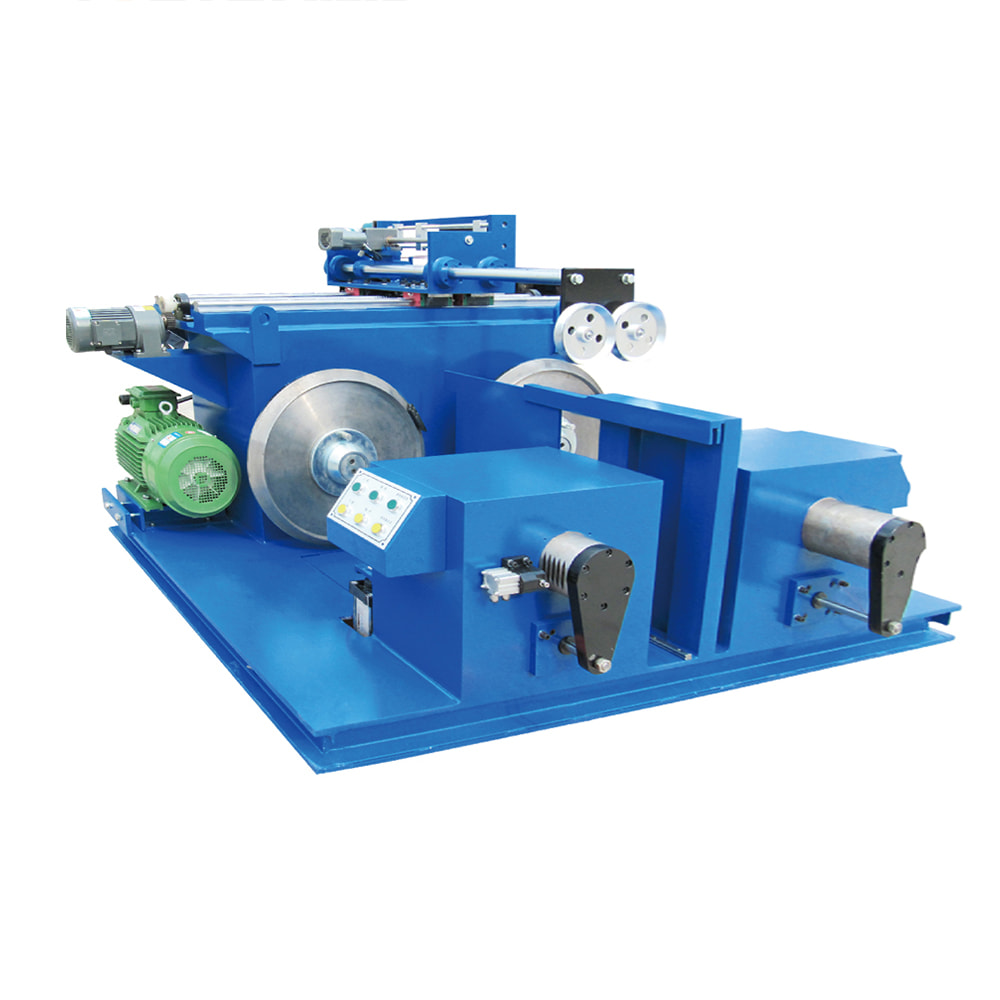

2. The winding shaft makes use of dual-frequency conversion synchronous control, leading to substantial energy savings and promoting more sustainable operation.

3. With the zero-slip pilot design, the machine attains high productivity and consistently manufactures finished wires of top-notch quality.

4. The electrical control system is equipped with an automatic memory function. This function ensures that during normal start-stop operations and restarts following a shutdown, no manual intervention is needed, and the machine can smoothly accelerate its operation.

| Model: | 24DT |

| Inlet diameter: | 0.6-1.2mm |

| Outlet diameter: | 0.1-0.3mm |

| Quantity of drawing dies: | 24 |

| Max. Drawing speed: | 2000m/min |

| Slip ratio of main machine: | 13% |

| Slip ratio of last die: | 8% |

| Using motor/ main motor: | 15KW |

| Usage: | Bare copper wire drawing |

| Correction system: | Automatically control |

| Annealing method: | DC three section annealing |

| Voltage: | 380V or Customized |

| Colour: | As customer's need |

| Brand: | Liqiang or OEM |

| Brake: | Pneumatic brake |

| Operation direction: | Right hand machine |

中文简体

中文简体 русский

русский Español

Español عربى

عربى