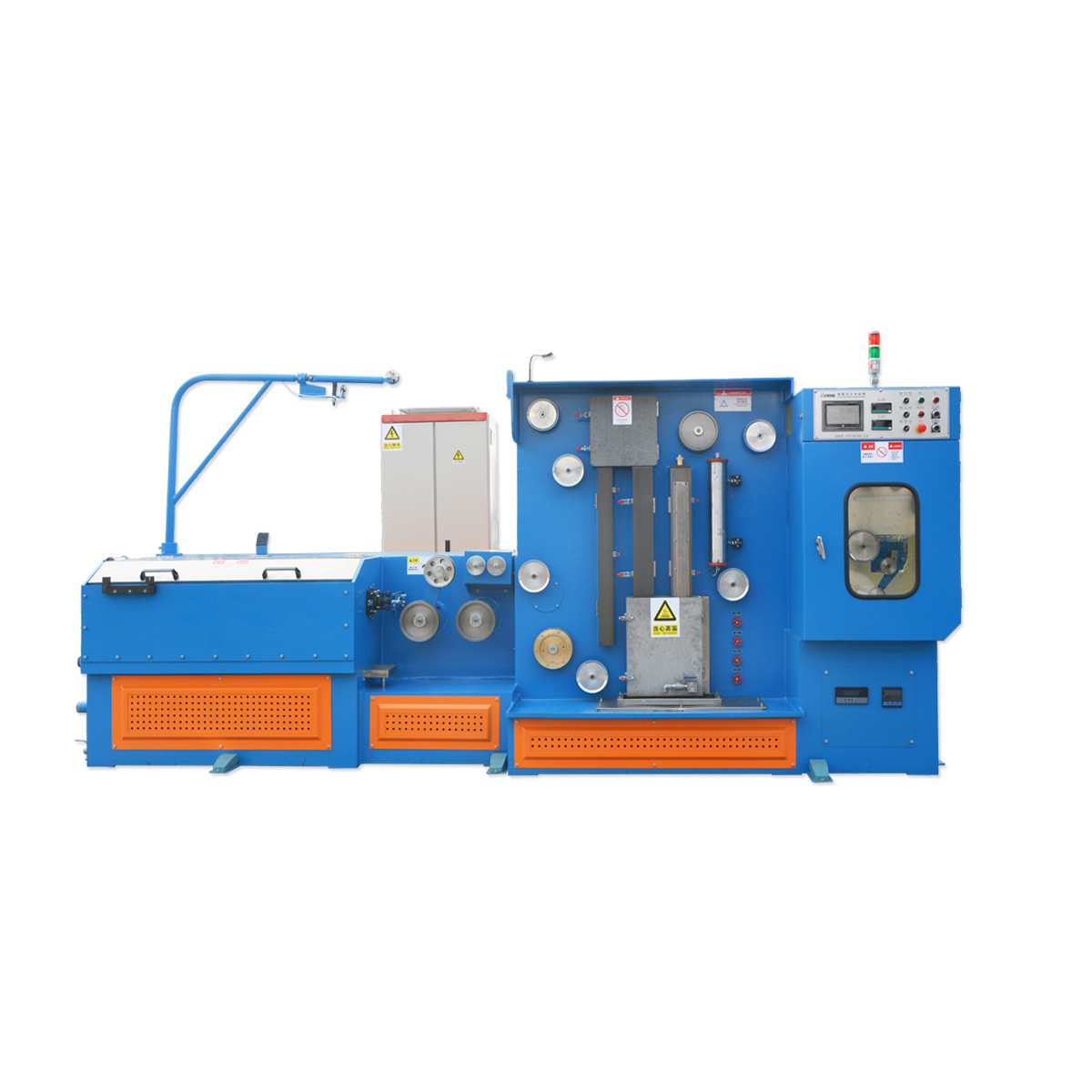

Introduction to Fine Wire Drawing Machines with Annealer

Fine wire drawing machines with annealers are specialized equipment designed to produce ultra-thin wires with precise diameter and enhanced mechanical properties. Combining the wire drawing and annealing process in one system ensures uniformity, reduces production time, and improves the overall quality of the wire.

Key Components of a Fine Wire Drawing Machine with Annealer

These machines typically include the following components:

- Wire Payoff: Feeds raw wire smoothly into the drawing machine.

- Drawing Dies: Precisely reduce the wire diameter through multiple stages.

- Annealer Unit: Heat-treats the wire to relieve stress and enhance flexibility.

- Tension Control System: Ensures uniform wire tension throughout the drawing process.

- Take-up Reel: Collects the finished wire while maintaining consistent winding.

Advantages of Integrating Annealing in Wire Drawing

Integrating an annealer with the wire drawing machine provides several significant advantages:

- Improved Wire Ductility: Prevents wire breakage during high-speed drawing.

- Enhanced Surface Quality: Reduces surface cracks and irregularities.

- Time and Energy Efficiency: Combines two processes into a single automated workflow.

- Consistent Mechanical Properties: Ensures uniform hardness and tensile strength across wire lengths.

Applications of Fine Wire Drawing Machines with Annealers

These machines are widely used across multiple industries due to their precision and efficiency:

- Electrical Wiring: Producing thin copper wires for high-performance electrical applications.

- Medical Devices: Manufacturing wires for surgical instruments and implants.

- Automotive Industry: Creating durable wires for sensors, connectors, and small components.

- Spring and Cable Manufacturing: High-quality wires for fine springs and cable assemblies.

Technical Parameters to Consider

When selecting a fine wire drawing machine with annealer, the following technical parameters are critical:

| Parameter |

Typical Range |

| Wire Diameter |

0.05 mm – 2.0 mm |

| Drawing Speed |

50 – 500 m/min |

| Annealing Temperature |

300°C – 600°C |

| Power Requirement |

5 – 50 kW |

Maintenance and Operational Tips

To ensure the longevity and optimal performance of a fine wire drawing machine with annealer, operators should follow these tips:

- Regularly inspect and replace worn drawing dies to maintain wire precision.

- Keep the annealing furnace clean and check temperature consistency frequently.

- Lubricate moving parts according to manufacturer recommendations.

- Monitor wire tension and speed to prevent breakage and surface defects.

- Schedule routine maintenance to prevent unexpected downtime.

Conclusion

Fine wire drawing machines with annealers provide a highly efficient, integrated solution for producing high-quality wires with consistent mechanical properties. By combining precise drawing with controlled annealing, manufacturers can reduce production time, improve wire durability, and meet the stringent requirements of modern industrial applications.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us