Introduction to Copper Wire Winding Machines

Copper wire winding machines are specialized devices used to coil copper wire into uniform and precise shapes for industrial applications. These machines are essential in manufacturing electrical motors, transformers, coils, and other electronic components. Proper use of a copper wire winding machine ensures efficiency, minimizes material waste, and improves product quality.

Types of Copper Wire Winding Machines

There are several types of copper wire winding machines designed for different production needs. Understanding these types helps manufacturers choose the right machine for specific applications.

Manual Winding Machines

Manual winding machines are operated by hand and are suitable for small-scale production or custom winding jobs. They are cost-effective but require skilled operators to maintain consistent winding quality.

Semi-Automatic Winding Machines

Semi-automatic machines combine manual input with motorized winding mechanisms. Operators load wire spools and adjust parameters, while the machine handles precise winding, increasing production efficiency and reducing human error.

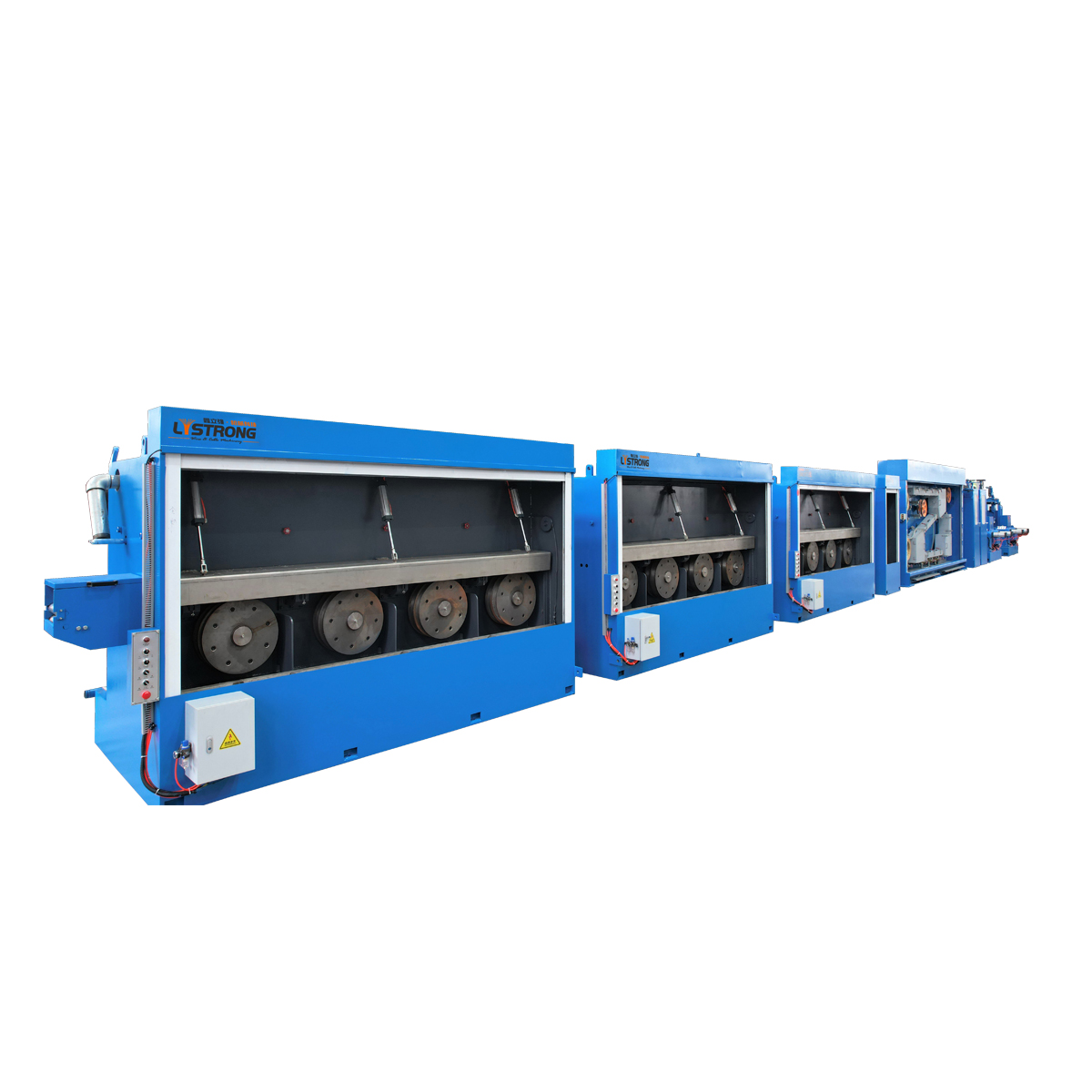

Fully Automatic Winding Machines

Fully automatic machines handle wire feeding, tensioning, and winding automatically. These machines are ideal for large-scale industrial production and ensure high accuracy, speed, and uniformity across multiple coils.

Applications of Copper Wire Winding Machines

Copper wire winding machines have versatile applications across various industries. They play a critical role in:

- Electric motor manufacturing

- Transformer coil production

- Inductor and solenoid coil fabrication

- Electromagnetic device manufacturing

- Custom wire coil designs for electronics

Key Features to Consider When Choosing a Machine

Selecting the right copper wire winding machine depends on several important factors that affect productivity and product quality:

| Feature |

Description |

| Wire Diameter Range |

The machine should support the range of copper wire diameters used in production. |

| Winding Speed |

Higher speeds increase productivity but must be balanced with precision requirements. |

| Automation Level |

Manual, semi-automatic, or fully automatic based on production scale. |

| Tension Control |

Ensures uniform winding and prevents wire breakage. |

Maintenance Tips for Optimal Performance

Proper maintenance is essential to extend the lifespan of a copper wire winding machine and maintain product quality. Key tips include:

- Regularly clean the machine to remove copper dust and debris.

- Lubricate moving parts to prevent friction and wear.

- Check wire tension mechanisms frequently to ensure consistent winding.

- Inspect electrical components for damage or loose connections.

- Replace worn-out parts promptly to avoid production downtime.

Conclusion

Copper wire winding machines are indispensable in modern manufacturing, offering precision, efficiency, and versatility. Choosing the right type and following proper maintenance practices ensures high-quality coils, reduces material waste, and maximizes production output.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us