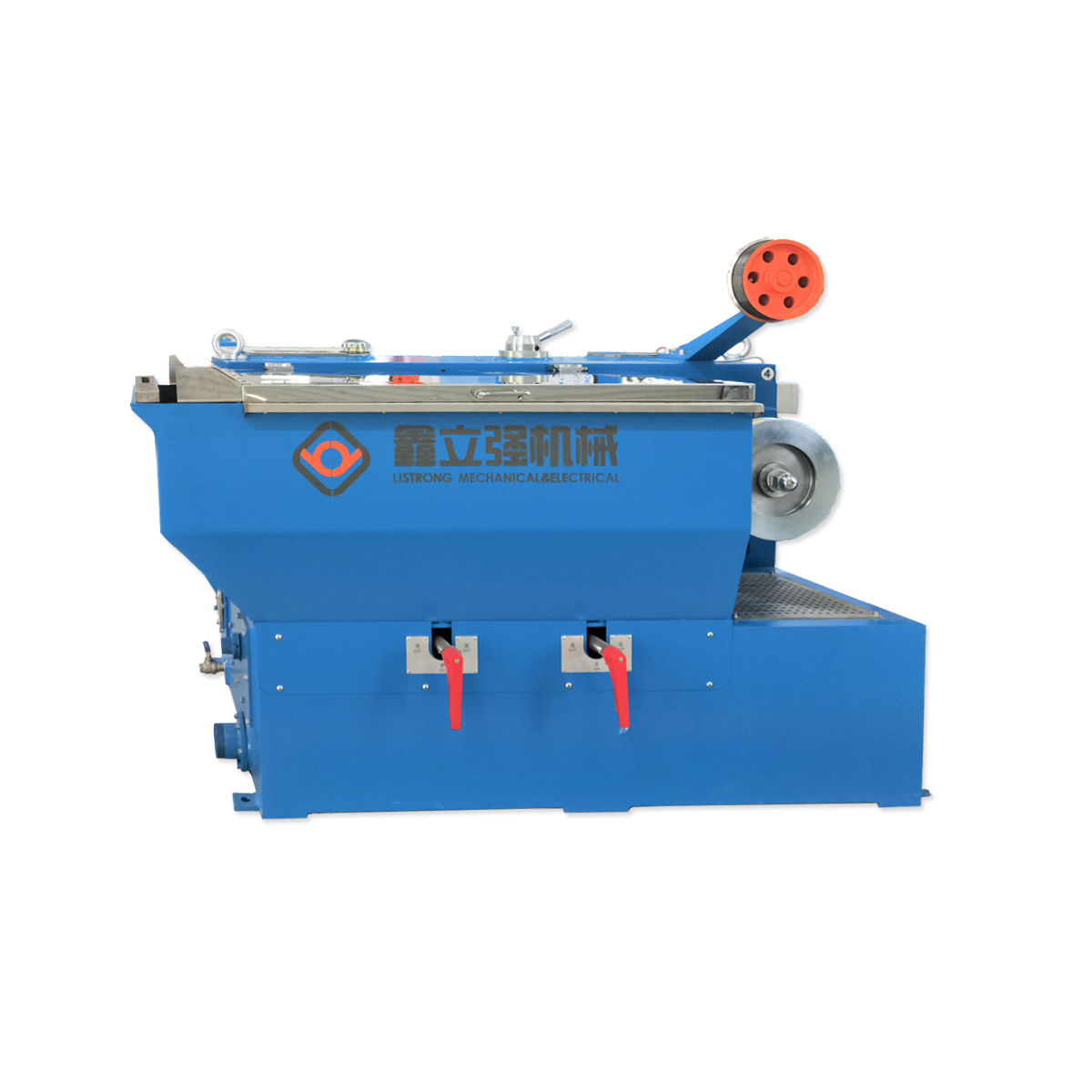

1. High precision helical gear transmission,unique oil lubrication mechanism,dual motor drive,fast die changing system;

2. Drawing oil lubrication using the die seat internal strong injection design.

3. More sufficient lubrication,save space,easy to operate;

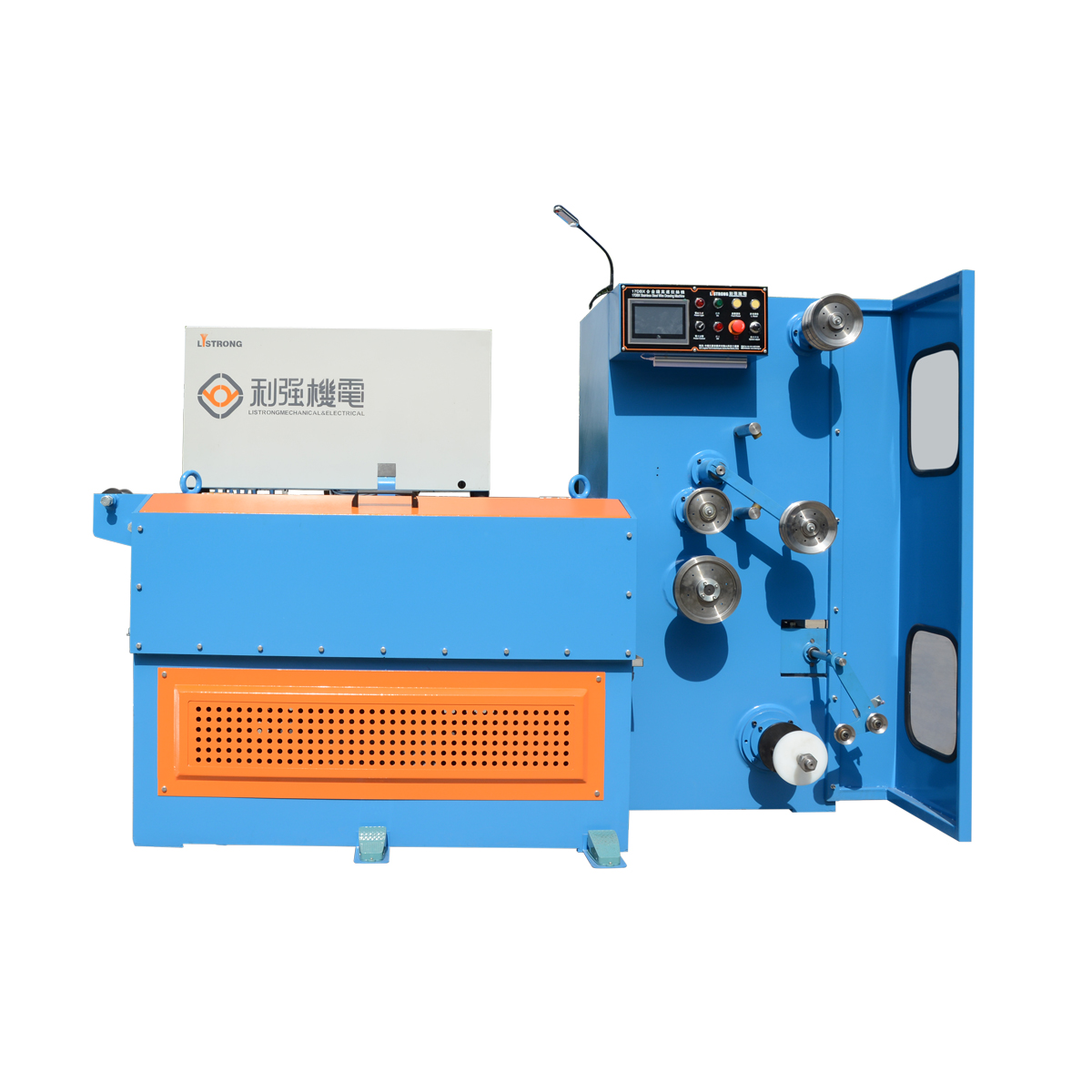

4. Annealing ring.nickel cylinder are made of special alloy material,ensures longer service life;

5. On-line annealing control adopts zero meter preset voltage design,ensures stable annealing quality of wire in start and stop state.

| Machine Type | DT100.200.24-25 |

| No.of wire | 24 |

| Inlet dia.(mm) | 1.80-2.00 |

| Outlet dia.(mm) | 0.15-0.40 |

| Max.speed(mpm) | 1800 |

| Max.number of drawing dies | 25 |

| Slip ration of M/C | 20%+15.5%+Outlet quick die change adjustment |

| Main machine power(kw) | 85KW+250KW+55KW |

| Drawing ring dia.(mm) | 100 |

| Annealing control method | DC |

| Contact pulley dia.(mm) | 200 |

| Annealing voltage(V) | 60 |

| Annealing current(A) | 5000 |

中文简体

中文简体 русский

русский Español

Español عربى

عربى