In high-volume production environments, reducing downtime is crucial for maintaining efficiency and profitability. This is especially true for automatic wire take up machines, which are often the backbone of modern wire manufacturing. To ensure these machines continue to perform at their best, it’s essential to develop and follow a robust maintenance strategy. While these machines are designed for durability, proactive maintenance is key to minimizing unplanned outages, extending the equipment's lifespan, and reducing overall operational costs.

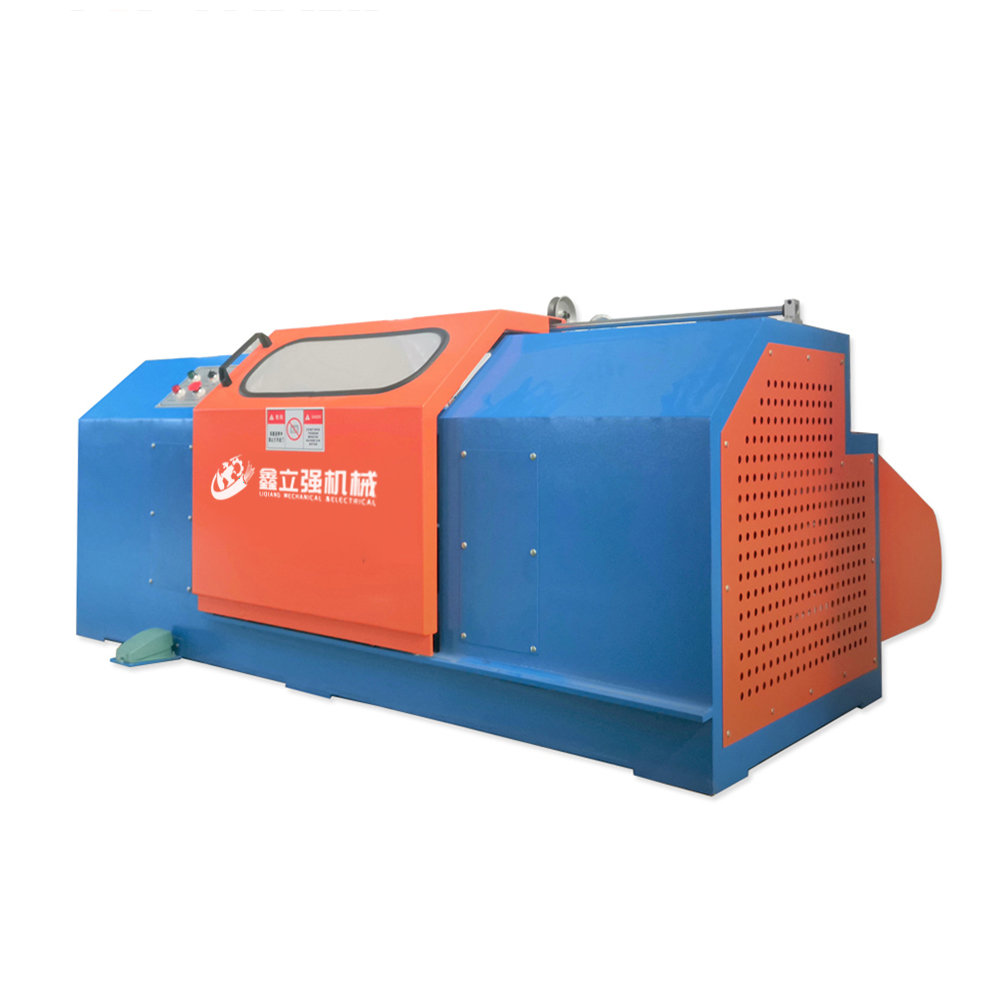

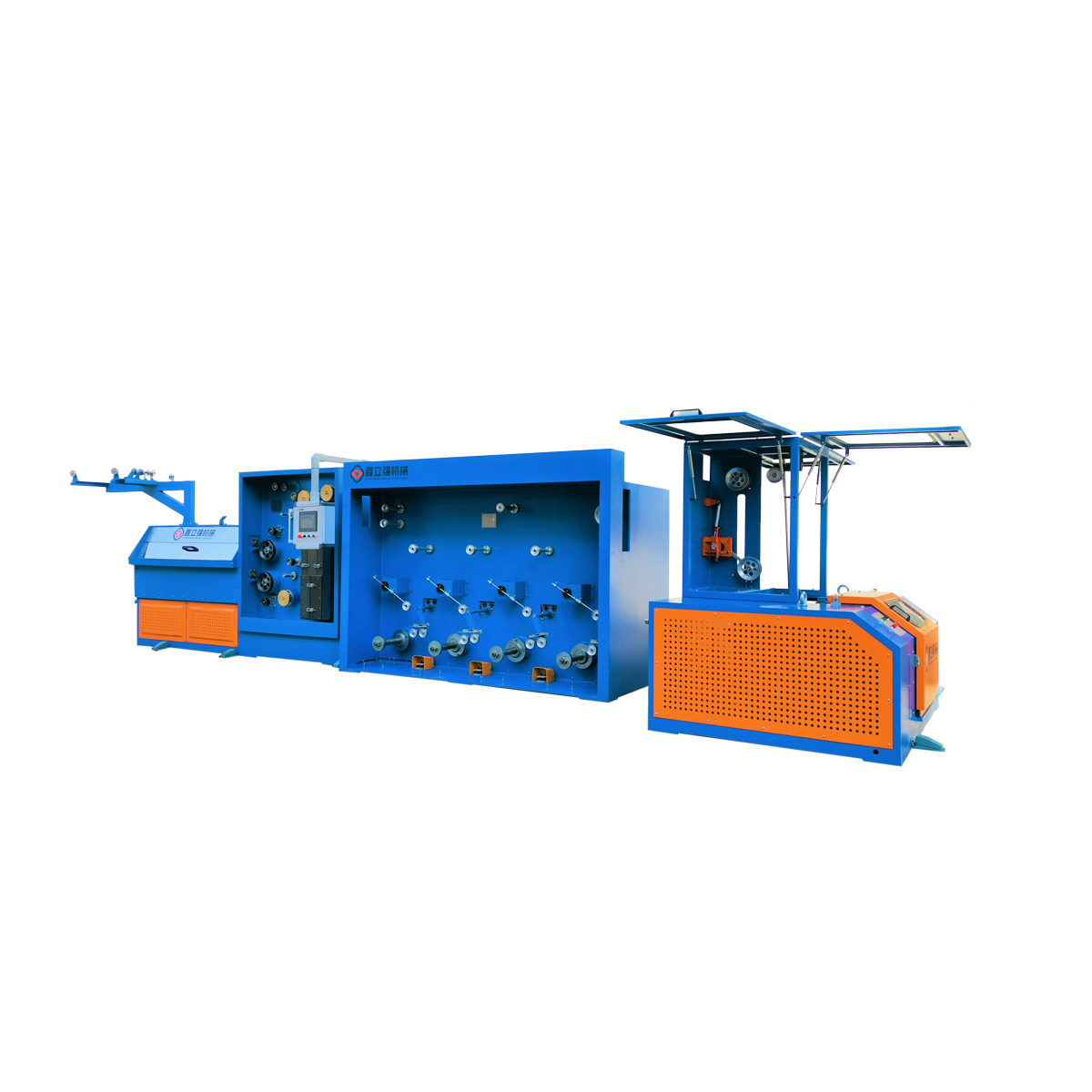

The first step in a comprehensive maintenance plan for an automatic wire take-up machine is understanding its key components. These machines typically include motors, sensors, electrical control systems, and mechanical elements like spools and tensioners. Each of these parts requires periodic inspection to prevent minor issues from escalating into major problems. For example, inspecting the motor bearings for signs of wear or checking the tension control system for proper calibration can prevent the breakdown of critical elements that could otherwise lead to production halts.

Another essential aspect of machine maintenance is proper lubrication. Over time, the moving parts of the wire take-up machine, including gears and spindles, can experience friction, which leads to wear and heat generation. Regular lubrication ensures that these parts continue to move smoothly, minimizing the risk of overheating and mechanical failure. It’s also important to use the correct type of lubricant, as different machines may require specific oils or greases to maintain optimal performance. Using high-quality lubricants not only improves machine efficiency but also reduces energy consumption and improves the overall reliability of the system.

Maintaining the electrical components of an automatic wire take-up machine is equally crucial. Since the machine's performance is heavily reliant on precise electrical control, any malfunction in the control systems can lead to inconsistent wire tension, coiling errors, or even machine stalling. Regular inspections of the PLC (Programmable Logic Controller), sensors, and motor drives are vital. Ensuring that the electrical connections are secure and free from corrosion can help avoid electrical failures that could otherwise disrupt production. Additionally, updating the machine’s software regularly to incorporate the latest features or fixes can also prevent unnecessary downtime.

Dust and debris are another common source of problems in wire production facilities. In an automatic wire take-up machine, particles can accumulate in sensitive areas like the motor housing or the spool assembly. Over time, this can lead to overheating, misalignment, or even damage to internal components. Scheduling periodic cleaning routines, where air pressure or vacuum systems are used to clear out buildup, is a simple but effective strategy to avoid these issues. Keeping the work environment clean not only ensures the longevity of the machine but also improves safety for operators.

Equally important is the regular calibration of the machine. This involves verifying that the wire is being wound with the correct tension and that the machine is correctly set up for each new wire type or batch. Even small changes in wire diameter, material, or tension can impact the machine’s performance. Calibrating the machine after each setup ensures that it continues to operate at peak efficiency, maintaining product quality and reducing waste. This is especially important when dealing with high-value materials like copper or aluminum, where even a slight deviation can result in significant material loss.

Lastly, investing in employee training is often an overlooked but essential part of a successful maintenance strategy. Operators should be well-versed in identifying early warning signs of wear and tear, such as unusual noise, vibration, or changes in wire quality. By catching problems early, operators can address minor issues before they escalate into costly repairs. Moreover, having an in-house team that understands the specific needs of an automatic wire take-up machine can help maintain a high level of operational efficiency and reduce reliance on outside maintenance providers.

For any manufacturer looking to optimize their wire production line, following a well-planned maintenance schedule for automatic wire take up machines is indispensable. By focusing on proactive care—from routine inspections to calibration and cleaning—businesses can ensure their equipment remains reliable, efficient, and cost-effective over the long term. Investing in maintenance not only helps prevent downtime but also maximizes productivity and extends the life of the machine, making it a valuable asset in any industrial operation.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us