In today’s fast-evolving industrial landscape, brass EDM wire has become a highly sought-after material for precision electrical discharge machining applications. Behind the scenes, the production of this critical wire relies heavily on advanced brass wire drawing machines that ensure exacting standards and consistent quality. These machines serve as the backbone of the brass EDM wire supply chain, enabling manufacturers to meet the rising market demand with efficiency and precision. Understanding how these wire drawing systems integrate into the broader production process sheds light on their indispensable role and the value they bring to customers seeking reliable brass wire products.

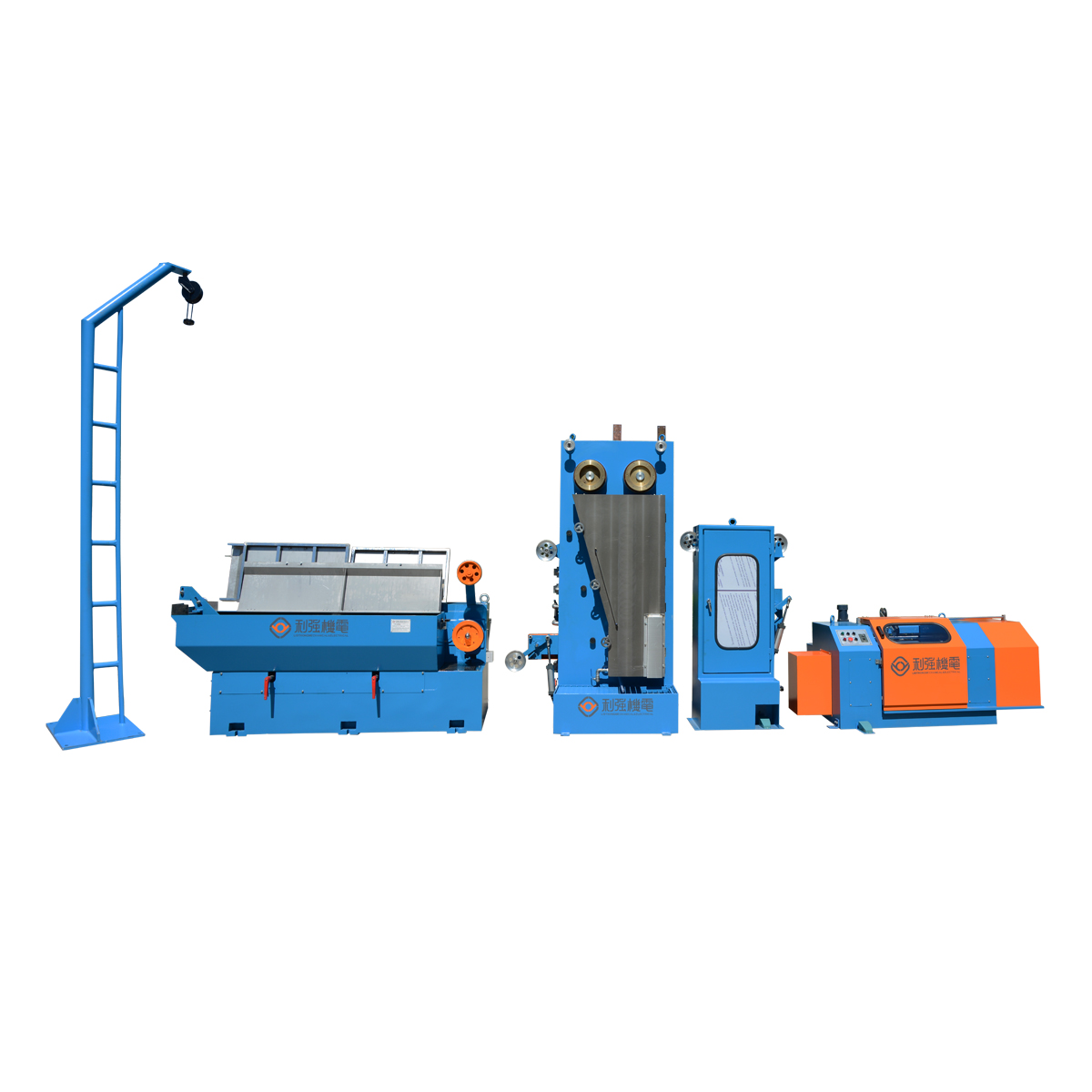

Brass wire drawing machines are engineered to handle the delicate task of reducing brass rods into fine wire sizes without compromising the material’s mechanical and electrical properties. The production of brass EDM wire demands a wire that maintains both strength and conductivity, qualities which are finely balanced during the drawing process. These machines, with their robust cast iron bodies and horizontal drawing arrangements, provide the stability and control needed to achieve uniform diameters and surface finishes essential for EDM applications. The precision tension control systems and automated PLC-driven operations further enhance this reliability, ensuring that each batch of wire meets stringent industry specifications.

As demand for brass EDM wire continues to grow across sectors such as automotive, electronics, and aerospace, the supply chain must respond swiftly and reliably. Brass wire drawing machines equipped with advanced control systems and flexible drawing capabilities allow manufacturers to quickly adapt production to different wire sizes, minimizing downtime and maximizing throughput. This agility is critical in a market where custom wire dimensions and just-in-time deliveries are becoming standard expectations. By investing in high-quality wire drawing technology, producers can maintain competitive lead times and fulfill diverse customer requirements with confidence.

The economic importance of brass EDM wire also reflects the broader trends in manufacturing where precision tooling materials are vital to product innovation and quality. Brass wire drawing machines contribute directly to this innovation by enabling the production of wire that meets the evolving performance criteria demanded by cutting-edge EDM processes. Their ability to maintain exact drawing tension and speed ensures that the wire exhibits the consistency and durability necessary for fine, intricate machining tasks. This precision ultimately supports manufacturers who depend on EDM wire for producing complex components with tight tolerances.

From a supply chain perspective, having reliable brass wire drawing equipment means less waste, lower production costs, and consistent delivery schedules. Machines designed with easy maintenance features, such as belt transmission and user-friendly Siemens PLC interfaces, reduce downtime and simplify operations, which translates to higher overall efficiency. For customers, this means access to top-quality brass EDM wire delivered on schedule, backed by the manufacturer’s assurance of product excellence and responsive after-sales support.

Furthermore, the integration of automatic correction control systems in modern brass wire drawing machines exemplifies how technology enhances product quality and operational stability. These systems automatically adjust coiling tension, reducing the risk of wire defects and ensuring uniformity across production runs. Such advancements highlight the ongoing commitment of machine manufacturers to improve the performance and reliability of their equipment, ultimately benefiting the entire brass EDM wire supply chain.

Brass wire drawing machines are a critical component in the production and supply of high-quality brass EDM wire, driving both industry innovation and customer satisfaction. Their precision, flexibility, and efficiency enable manufacturers to meet growing demand and maintain strict quality standards, making them an indispensable asset in the modern industrial ecosystem. Choosing the right brass wire drawing equipment means investing not only in superior machinery but also in a smoother, more dependable supply chain — a compelling advantage for any business relying on premium brass EDM wire.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us