Introduction to Rod Breakdown Machines

Rod breakdown machines are critical in the wire manufacturing process, particularly in industries where high volumes of wire need to be processed efficiently. These machines are designed to reduce the diameter of wire rods, enabling the production of smaller diameter wires. Understanding the breakdown process and the mechanics behind rod breakdown machines helps in optimizing wire production and improving overall efficiency.

1. Overview of the Rod Breakdown Process

Rod breakdown is a key step in the wire drawing process, where large diameter rods are progressively reduced in size to meet the specifications required for the final product. The rod breakdown machine, which is also known as a wire drawing machine, ensures that the wire maintains consistent quality and strength during the reduction process. This section outlines the stages involved in rod breakdown.

1.1 Initial Setup

Before the rod breakdown process begins, the raw material, typically copper, aluminum, or steel, is prepared. The wire rod is loaded onto the machine, and the tension settings are adjusted according to the material's properties and the required final diameter. The machine operator sets up the wire drawing dies and ensures that the lubricating system is functioning properly.

1.2 Drawing Process

During the drawing process, the rod is pulled through progressively smaller dies, reducing its diameter. The machine applies a continuous pulling force, which elongates the wire while maintaining its tensile strength. This step is typically repeated multiple times, with each pass reducing the wire's diameter further until the desired gauge is achieved.

1.3 Cooling and Lubrication

As the wire is drawn, it generates heat due to friction. To prevent overheating, a cooling system is used to lower the temperature of the wire. Additionally, a lubrication system is employed to reduce friction between the wire and the dies. This ensures that the wire remains smooth and free from defects throughout the process.

1.4 Final Stage

Once the wire reaches the desired diameter, it passes through a final die and is coiled into spools. The finished wire is then inspected for quality, checking for uniformity in diameter, surface finish, and strength. The spools of wire are ready for further processing or shipment to the next stage of production.

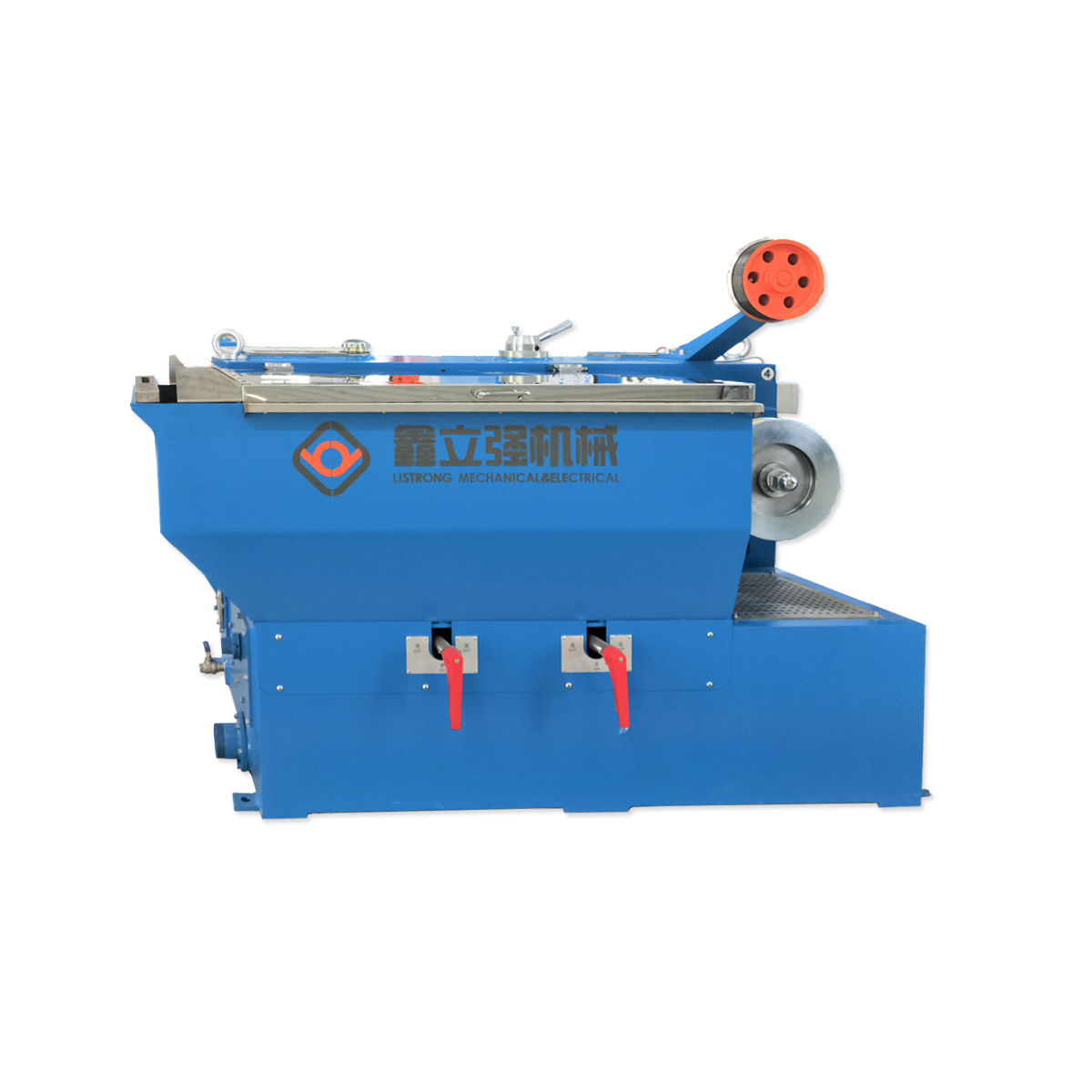

2. Key Components of a Rod Breakdown Machine

Rod breakdown machines are made up of several key components that work together to achieve the drawing process efficiently. These components include:

- Drawing Dies: These are the tools through which the wire is pulled to reduce its diameter. They are critical in determining the final size and quality of the wire.

- Wire Spool: After the wire has been drawn, it is wound onto a spool for storage and easy handling.

- Tension Control System: Ensures the wire is drawn with the proper force and consistency. It also helps to avoid wire breakage.

- Lubrication System: Helps reduce friction during the drawing process and ensures a smooth finish on the wire.

- Cooling System: Prevents the wire from overheating, which could cause defects or material degradation.

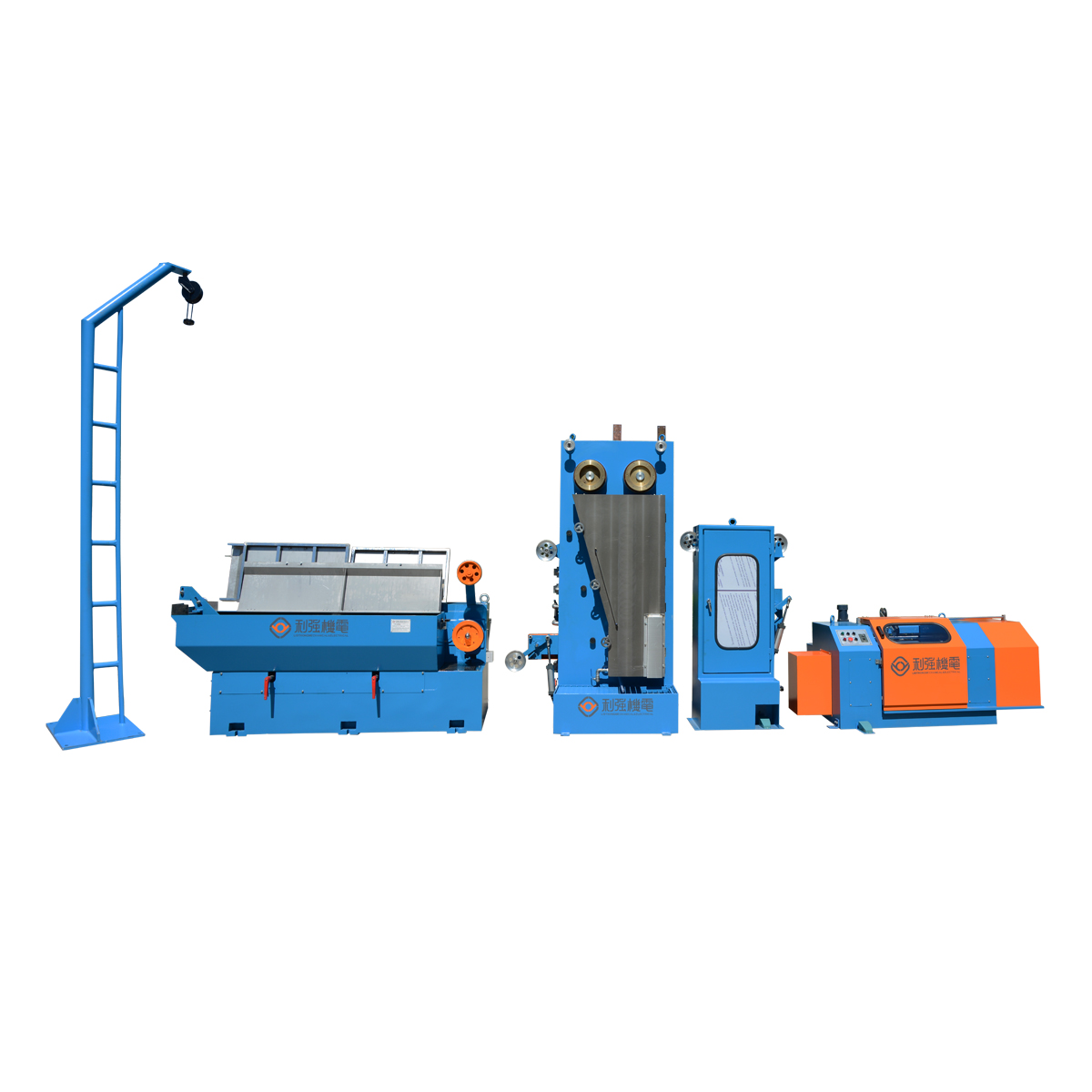

3. Types of Rod Breakdown Machines

There are different types of rod breakdown machines, each designed to handle specific tasks based on the wire material, diameter, and required output. The most common types include:

- Single-Block Rod Breakdown Machines: These machines are typically used for high-volume production of smaller diameter wires.

- Multi-Block Rod Breakdown Machines: Used for larger diameter rods that require multiple drawing stages to achieve the final size.

- Planetary Rod Breakdown Machines: These machines use planetary motion for greater precision and are used for producing wires with very tight diameter tolerances.

4. Challenges and Solutions in Rod Breakdown Machines

While rod breakdown machines are highly effective, they do come with certain challenges that can impact production quality and efficiency. Some of the common issues include:

- Wire Breakage: This can occur if the tension is too high or the lubrication is inadequate. Regular maintenance and tension adjustments are critical to preventing this.

- Overheating: Excessive heat can damage the wire and the machine. Effective cooling systems and proper machine settings help avoid this issue.

- Quality Control: Ensuring consistent wire diameter and surface finish can be challenging. Using high-quality dies and performing regular inspections can minimize defects.

5. Conclusion

Rod breakdown machines play a pivotal role in wire manufacturing, offering efficiency and precision in the reduction of wire rod diameters. By understanding the key stages, components, and potential challenges, manufacturers can optimize the process and improve the quality of the final product. With advancements in technology, these machines continue to evolve, offering better performance, greater energy efficiency, and improved wire quality.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us