What Are Steel Wire Drawing Machines?

Steel wire drawing machines are essential pieces of equipment used in the production of wire from steel rods. They work by pulling the steel through a die to reduce its diameter, which increases its length. These machines are crucial in industries that require high-precision steel wires for various applications, including automotive, construction, and electrical sectors.

How Steel Wire Drawing Machines Work

The wire drawing process involves the reduction of a wire's diameter by pulling it through a die with a smaller diameter. This method elongates the wire, improving its strength and flexibility. The process can be continuous, with the wire being drawn over multiple stages to reach the desired thickness.

The key components of a steel wire drawing machine include:

- Drawing die: This is the core component responsible for reducing the wire's diameter.

- Capstan: The rotating drum that pulls the wire through the die.

- Wire guide: It helps direct the wire into the drawing die, ensuring a smooth and consistent pull.

- Lubrication system: This reduces friction and heat during the drawing process, extending the life of the machine and improving the wire's quality.

Types of Steel Wire Drawing Machines

There are several types of steel wire drawing machines, each designed for specific applications and wire types. The main types include:

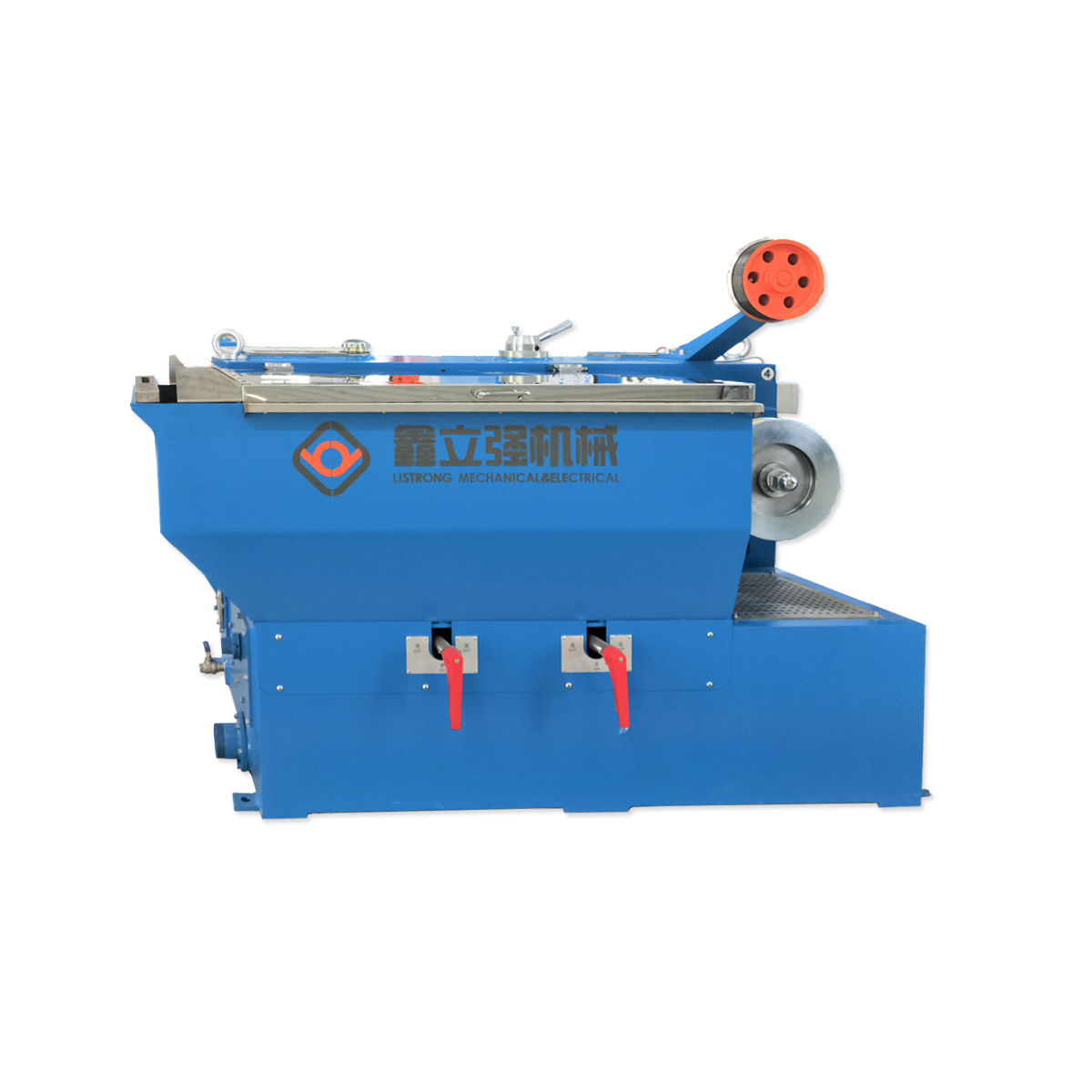

1. Single-Block Drawing Machines

These machines feature a single die and are typically used for drawing relatively small quantities of wire. They are compact and easy to operate but may not be as efficient for high-volume production.

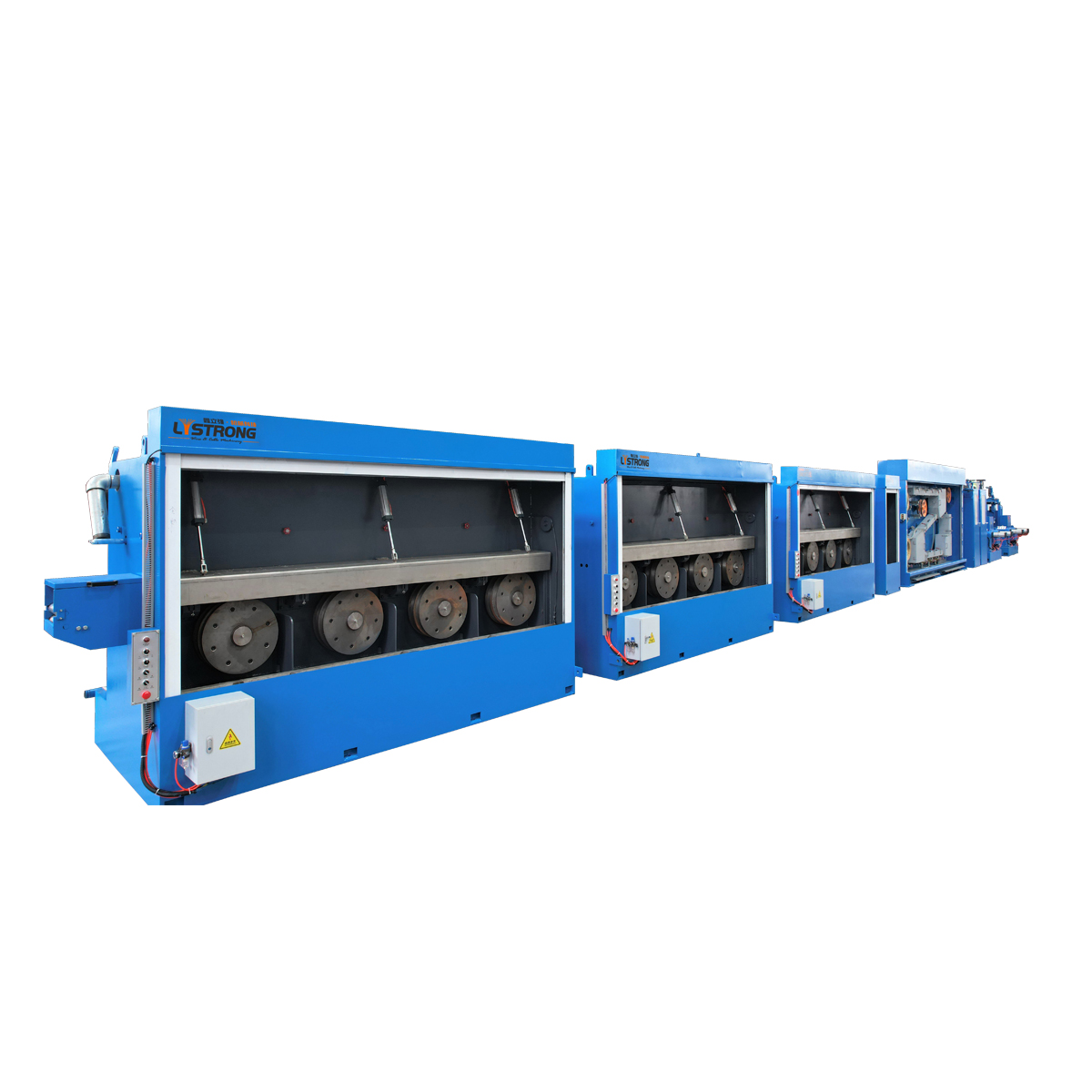

2. Multi-Block Drawing Machines

Multi-block machines feature several drawing blocks that allow for the continuous drawing of wire in multiple stages. These machines are highly efficient for large-scale wire production, as they can handle larger volumes and produce finer wires.

3. Horizontal and Vertical Drawing Machines

In horizontal machines, the wire is drawn through horizontal dies, while in vertical machines, the dies are oriented vertically. Vertical machines are typically used for higher precision and faster drawing speeds, whereas horizontal machines are simpler and more cost-effective for less complex tasks.

Applications of Steel Wire Drawing Machines

Steel wire drawing machines are used in various industries, producing wires for different purposes. Key applications include:

- Automotive: Steel wires are used for springs, cables, and other components that require strength and flexibility.

- Construction: Steel wire is vital for reinforcement bars and mesh used in concrete structures.

- Electrical: Wires for electrical cables, including those used for power transmission and communication, are often made using wire drawing machines.

- Manufacturing: Steel wires are used in products like nails, fasteners, and wire mesh.

Maintenance Tips for Steel Wire Drawing Machines

Regular maintenance of steel wire drawing machines is crucial to ensure their efficient operation and extend their service life. Here are some essential maintenance practices:

- Lubrication: Ensure that the drawing dies and the wire guides are properly lubricated to reduce friction and prevent overheating.

- Inspection: Regularly inspect the drawing dies for wear and tear, replacing them when necessary.

- Cleaning: Clean the machine components, such as capstans and guides, to prevent the buildup of debris and dirt that can impair performance.

- Alignment checks: Periodically check the alignment of the drawing dies to ensure they are properly positioned for optimal wire drawing.

Conclusion

Steel wire drawing machines play a critical role in producing high-quality steel wires for various industrial applications. Understanding how they work, the different types available, their applications, and proper maintenance practices can help businesses maximize efficiency and reduce downtime. Whether for low or high-volume production, these machines are fundamental in creating wires that meet the exacting standards required by industries worldwide.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us