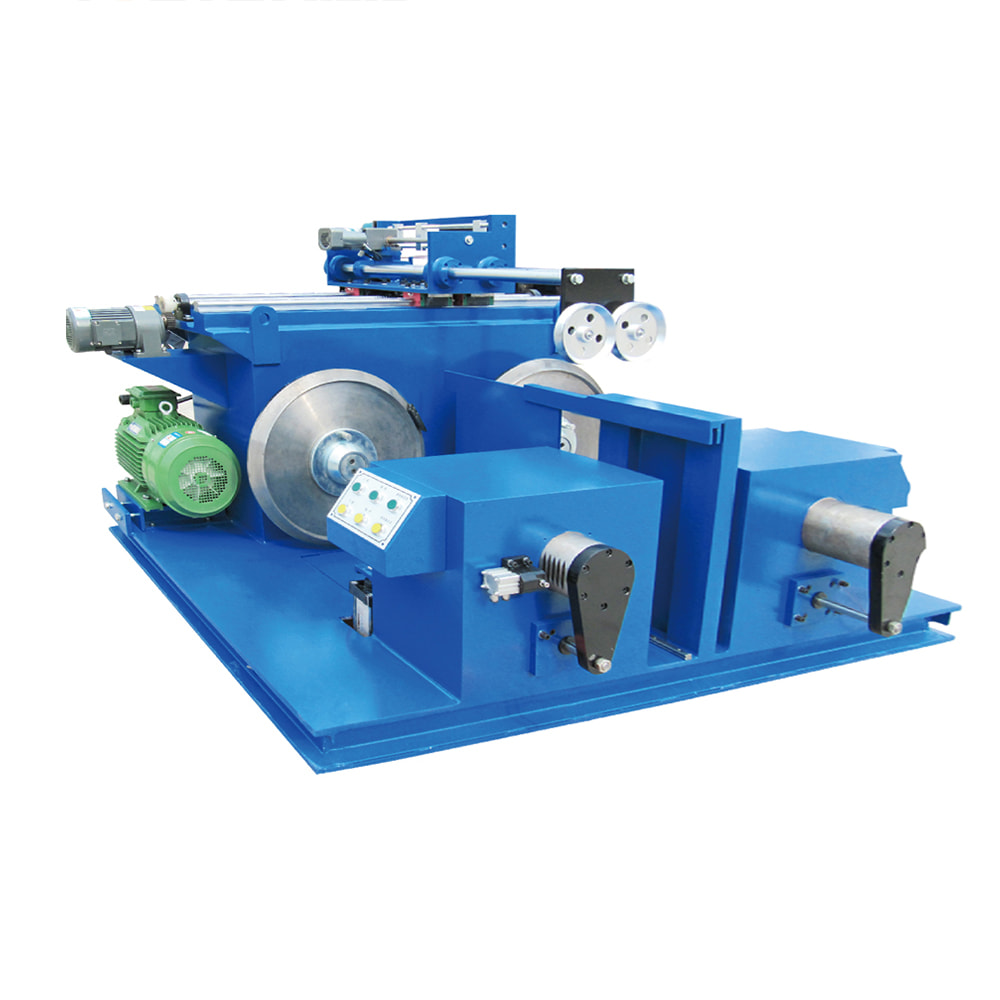

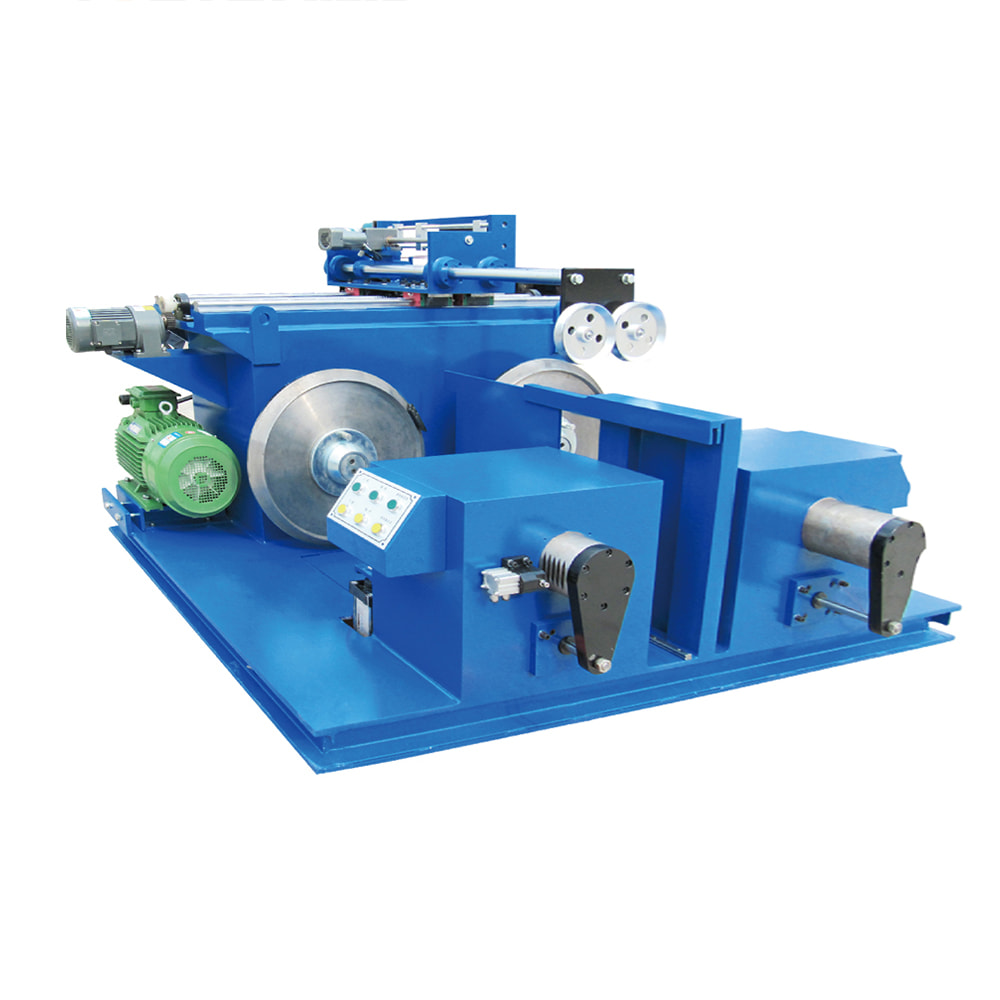

Maintaining consistent wire tension is one of the most critical yet often underestimated aspects of wire processing. In the context of an Automatic Wire Take-up Machine, stable tension directly affects coil quality, machine coordination, and overall production efficiency. If tension fluctuates even slightly during coiling, it can lead to uneven layers, loose loops, or even wire breakage—issues that can compromise downstream usability or packaging standards. Especially when handling high-speed operations or varying wire diameters, precise tension control is not just a preference but a necessity.

An automatic wire coiling system relies on coordinated interaction between the take-up unit, the dancer arm or tension feedback system, and the motor drive controls. In many machines, servo or inverter-controlled motors adjust torque in real time based on feedback from load cells or tension sensors. This dynamic response ensures that tension remains within a controlled window, even as line speed or wire properties change. For example, aluminum and copper wires respond differently to pulling forces due to their elasticity and softness, so adaptive tension regulation is crucial when your take-up machine is expected to handle a range of materials.

Another key factor is the synchronization between the wire take-up machine and upstream equipment such as extruders, wire drawing machines, or annealers. If the take-up speed is not perfectly tuned to match the wire feed rate, the system will either introduce slack or apply excessive pull, both of which disrupt production. Advanced take-up systems often feature programmable logic controllers (PLCs) to coordinate this synchronization, which is especially useful when switching between wire sizes or material types mid-shift. A properly integrated line doesn’t just improve tension—it optimizes the entire workflow.

Physical components also play a critical role in tension stability. The design of the dancer mechanism, guide rollers, and spool support structure must reduce friction and allow smooth transitions of the wire path. Poor alignment or low-quality rollers can create micro-vibrations or drag, making tension readings unreliable. Manufacturers who focus on the structural stability and mechanical precision of their automatic wire take-up units give customers a real advantage in long-term performance and product consistency.

Of course, not all wires behave the same during coiling. Fine-gauge wires are particularly sensitive to over-tensioning and may stretch or deform if not carefully handled, whereas larger-diameter steel or brass wires may resist bending, putting additional stress on drive systems. A well-designed take-up machine must allow users to adjust parameters such as spool torque, coil diameter, and back tension depending on the material. Some systems even offer recipe settings for recurring jobs, enabling faster setup and fewer errors in repeat production runs.

Maintaining wire tension is not just about machine capability—it also requires proper setup and maintenance routines. Operators should regularly check calibration of sensors, inspect guide paths for wear or misalignment, and verify that motor control settings match the production specifications. Training your team to understand the tension control logic within the take-up machine can reduce trial-and-error downtime and extend the lifespan of both equipment and coiled product.

From a buyer’s perspective, the ability of an automatic wire take-up system to maintain tension accurately should be one of the core evaluation criteria. It reflects the level of engineering behind the machine and strongly correlates with reduced rework, smoother downstream processing, and higher end-product quality. As a professional manufacturer in this field, we’ve seen how even minor improvements in tension regulation can lead to major gains in productivity and customer satisfaction.

Choosing an Automatic Wire Take-up Machine that balances advanced control systems with solid mechanical design ensures your operation runs smoothly, even under demanding conditions. If you're scaling up your production or working with diverse wire types, investing in a well-calibrated, tension-optimized take-up system isn't just a technical upgrade—it’s a strategic move for your business.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us