Introduction

Wire drawing is a fundamental metalworking process used to reduce the cross-section of a wire by pulling it through a series of dies. Traditionally, this process has been performed using horizontal or standard vertical wire drawing machines. However, the inverted vertical wire drawing machine presents a unique and innovative configuration that offers specific advantages for drawing large-diameter wires or when dealing with coils that are heavy, difficult to handle, or require precision and safety.

This article explores the design, function, advantages, applications, and technical considerations of the inverted vertical wire drawing machine.

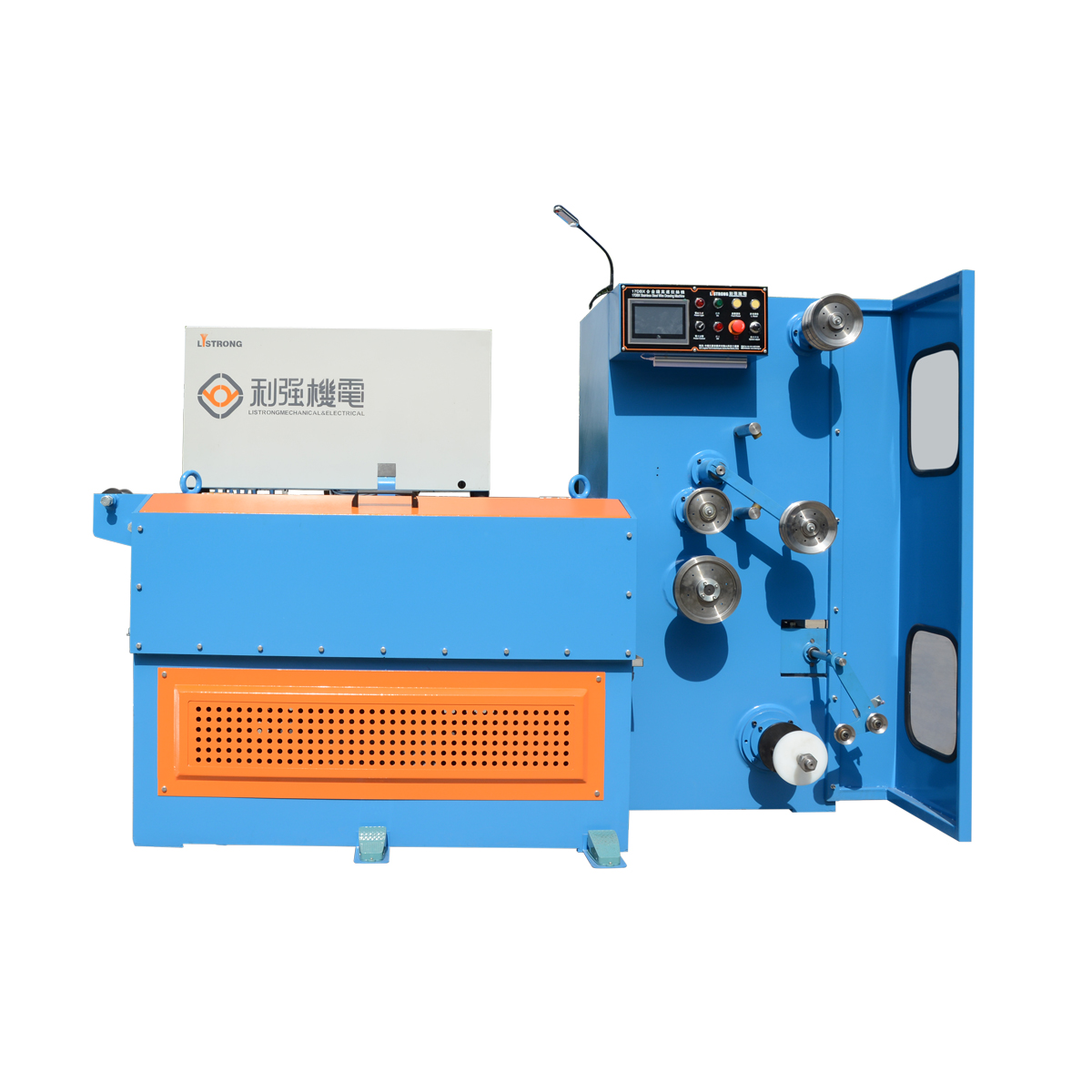

1. What is an Inverted Vertical Wire Drawing Machine?

An inverted vertical wire drawing machine is a type of wire drawing equipment where the capstan (drawing drum) and take-up system are located below the die, in contrast to conventional machines. In this configuration, the wire is drawn upward through the die, and then wrapped around the capstan or directly coiled into a large bundle (coil) above or nearby. This inverted setup is especially effective for drawing large-diameter wires or low-ductility materials like steel, stainless steel, copper, and aluminum.

Core Principle:

The drawing capstan is located below the die.

Wire is drawn vertically upward.

Coiling is done above the drawing mechanism.

2. Design and Working Principle

The typical layout of an inverted vertical wire drawing machine includes the following components:

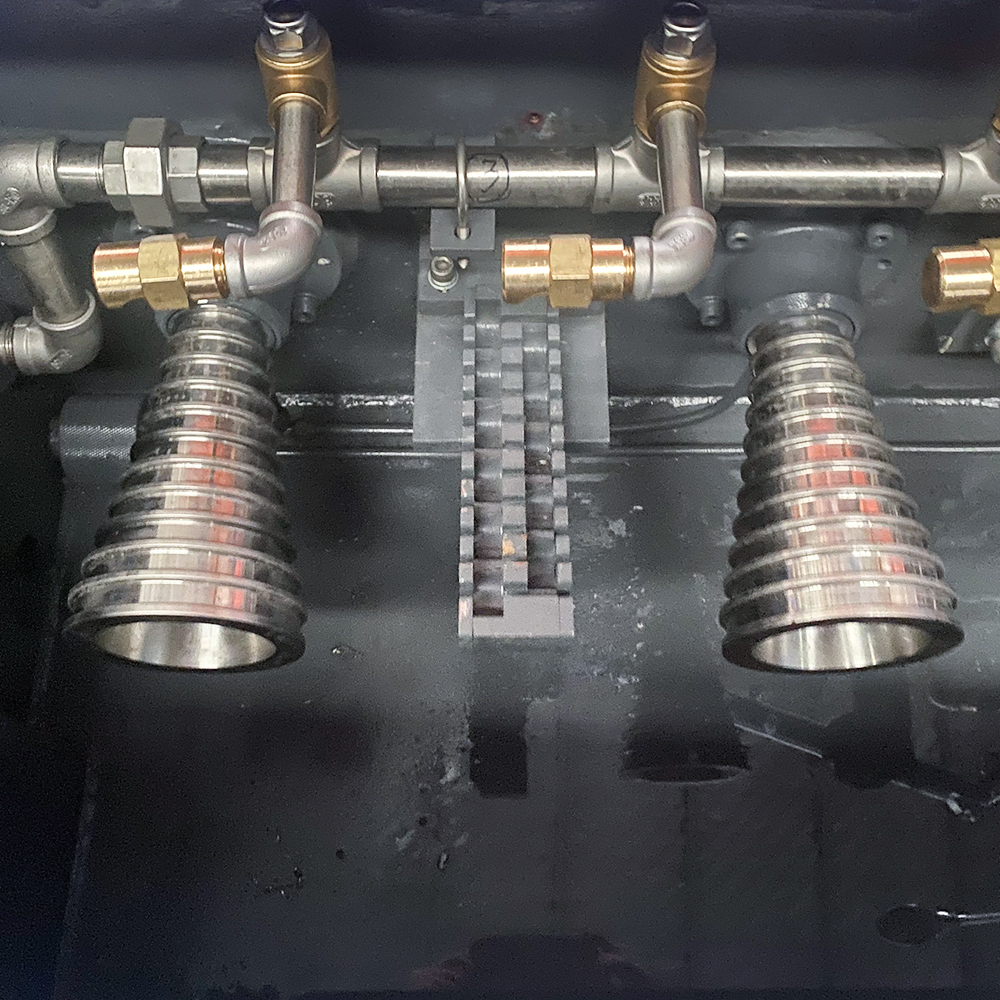

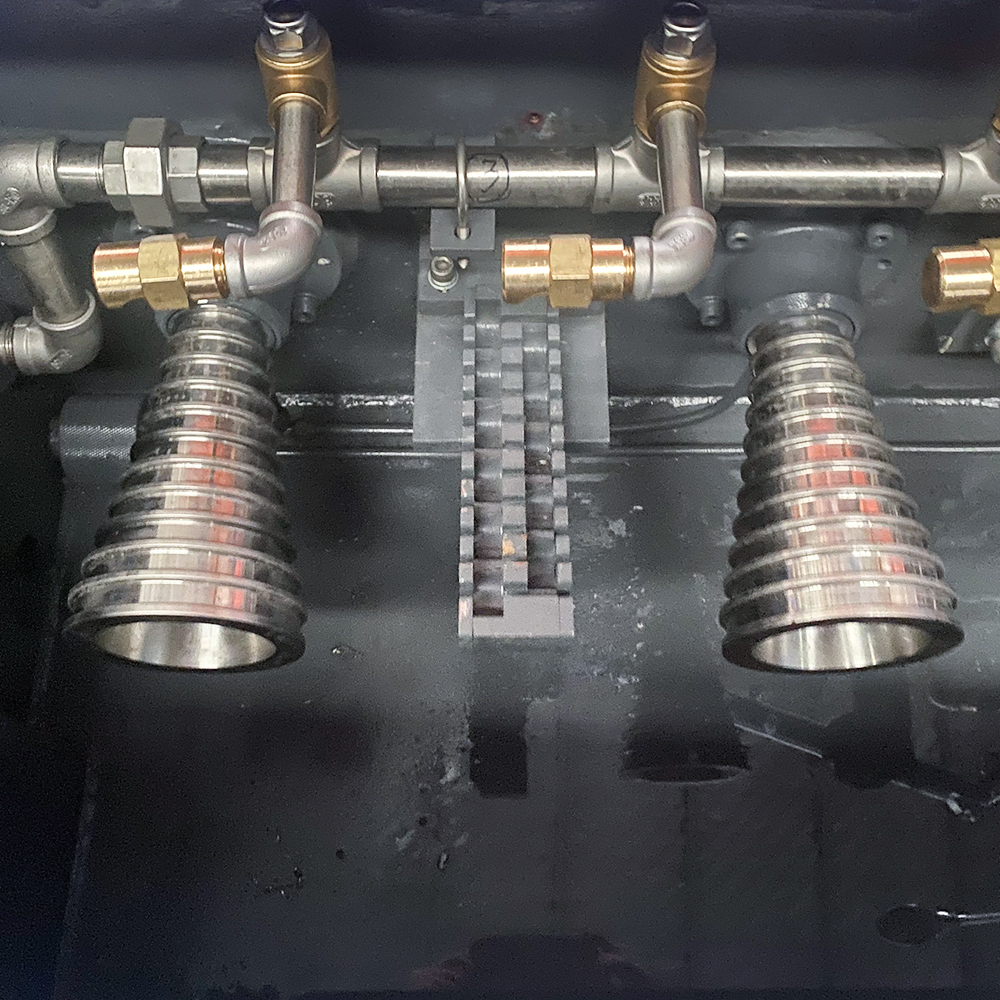

a. Die Box and Die Holder

The die, often made from tungsten carbide or polycrystalline diamond (PCD), is mounted in a die box that may include cooling or lubrication systems.

b. Drawing Capstan (Drum)

Positioned below the die, the capstan pulls the wire upward. It is often grooved or coated with hardened material for wear resistance. It is driven by a motor with precise torque control.

c. Take-Up System

Unlike traditional machines that pull the wire downward, inverted vertical machines allow the wire to coil into large vertical baskets or spools placed above the machine or to one side.

d. Lubrication System

Dry or wet drawing lubricants are used depending on the material. The vertical orientation helps drain and reuse lubricants efficiently.

e. Control System

Modern machines use PLCs (programmable logic controllers) and HMI (human-machine interface) panels for speed, torque, and synchronization control.

3. Advantages of Inverted Vertical Configuration

a. Gravity-Assisted Coiling

The machine benefits from gravity to naturally help guide the wire into large coils or carriers, especially useful for heavy-gauge wires.

b. Reduced Wire Bending

There is minimal bending stress as the wire is drawn in a straight vertical line, reducing the risk of breakage and improving surface finish.

c. Ease of Handling Large Coils

Inverted vertical machines are ideal for large wire coils that are difficult to manage in traditional horizontal setups.

d. Improved Lubrication Recovery

As gravity pulls excess lubricant down, it can be collected more efficiently, resulting in cleaner operation and lower lubricant consumption.

e. Compact Floor Space

Since much of the drawing operation is vertical, these machines can be more space-efficient in some factory layouts.

4. Applications

The inverted vertical wire drawing machine is primarily used in the following sectors:

Steel wire industry (carbon steel, alloy steel, stainless steel)

Electrical wire manufacturing

Heavy-duty copper or aluminum wire processing

Prestressed concrete steel strand (PC strand) production

Welding wire manufacturing

Cold heading wire production

5. Technical Considerations

a. Wire Material and Diameter

Typically used for wire diameters from 5 mm up to 30 mm, depending on machine capacity.

Ideal for hard-drawing materials or when minimal deformation per pass is needed.

b. Die Selection and Wear

The vertical orientation requires strong, wear-resistant dies.

Constant monitoring is needed to detect wear and prevent diameter inconsistencies.

c. Motor and Drive

High-torque motors and variable frequency drives (VFDs) are used for speed regulation.

Energy-efficient motors can reduce operational costs significantly.

d. Cooling and Lubrication

High-temperature rise due to friction requires efficient cooling.

Dry powder or oil-based lubricants must be compatible with vertical flow dynamics.

e. Safety Features

Guarding against accidental contact with moving vertical wires.

Emergency stop systems and load sensors to prevent over-tensioning.

6. Variants and Customizations

Single-capstan or multi-capstan machines

Wet or dry drawing

Inline annealing (for copper or aluminum wire)

Coil transfer systems (automated or manual)

Integration with straightening or cutting equipment

7. Limitations

Higher initial cost compared to horizontal machines

May require higher vertical clearance in facilities

Not ideal for ultra-fine wire drawing (better suited for coarse gauges)

Die alignment must be precise to avoid vertical vibration or wobble

8. Recent Technological Developments

AI-based quality control for surface inspection

IoT-enabled monitoring for predictive maintenance

Smart lubrication systems to optimize usage and environmental impact

Energy regeneration systems to recover braking energy

Conclusion

The inverted vertical wire drawing machine is a powerful evolution in wire production technology. Its upward drawing mechanism and gravity-assisted take-up system provide clear benefits in handling large and heavy wires, ensuring product quality, reducing mechanical stress, and improving operator safety. As manufacturing demands shift toward higher performance and energy efficiency, this type of machine continues to gain traction in heavy industrial wire processing.

By understanding its design, functionality, and applications, manufacturers can leverage its advantages to increase productivity, reduce waste, and enhance overall process efficiency.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us