What is a Bunching Machine?

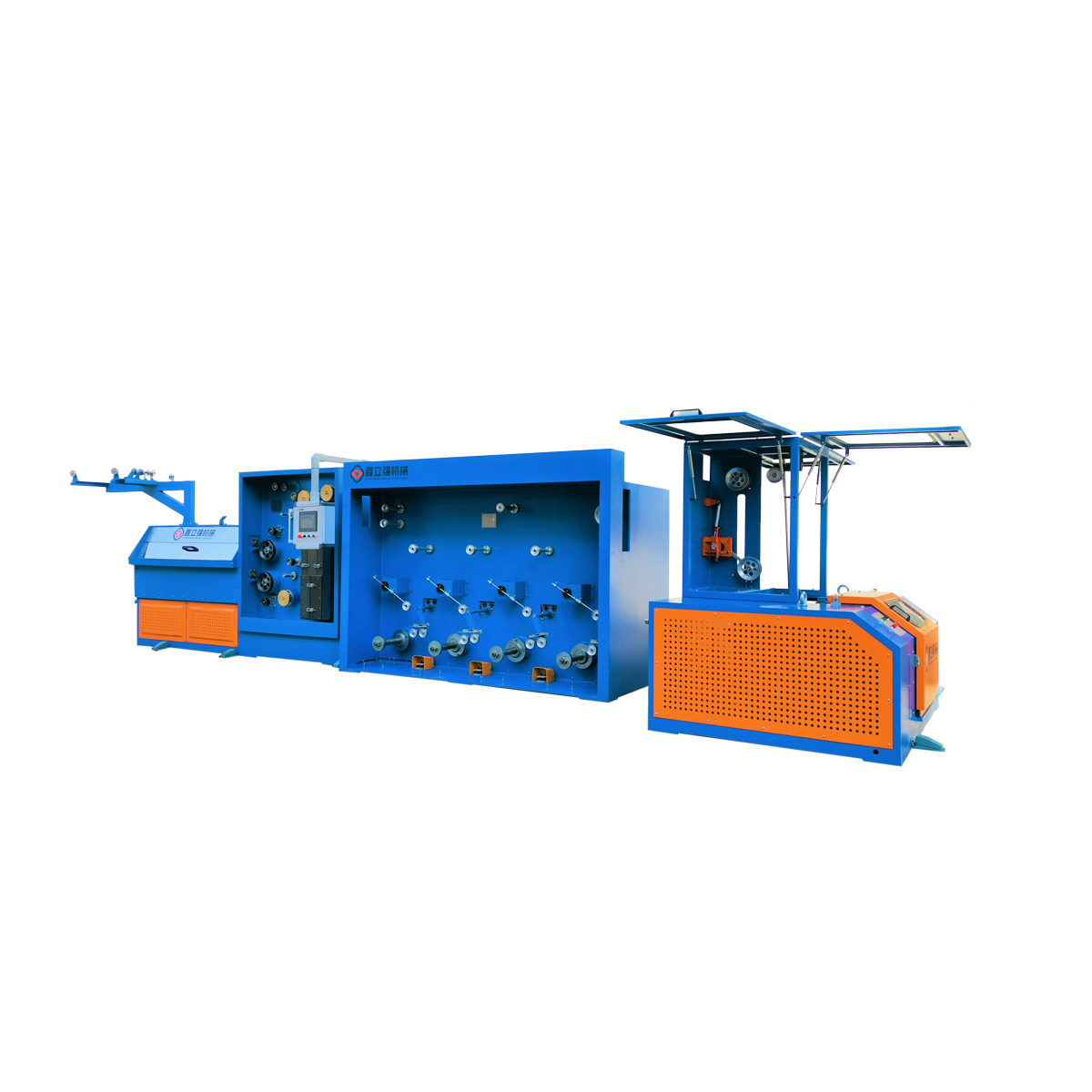

A bunching machine is an industrial device designed to automatically twist together multiple strands of wire—typically bare copper or tinned copper—into a single, uniform cable. This twisting process, known as bunching, is critical in the wire and cable manufacturing industry as it enhances the mechanical strength, flexibility, and electrical performance of the final product.

How It Works

The core function of a bunching machine is to spin multiple wires at high speed around a central axis, intertwining them into a cohesive bundle. Unlike simple twisting, which may involve just two wires, bunching involves several strands (sometimes dozens) being combined in a consistent helical pattern. This process ensures that the final cable maintains uniform electrical properties and durability across its length.

Key Features of Modern Bunching Machines

High-Speed Twisting: Modern machines operate at high speeds to meet industrial production demands. Despite the rapid motion, they maintain stable working performance, ensuring precision and repeatability in every batch.

Versatility: They are capable of handling wire cables of various sizes, making them adaptable for different production requirements—from fine electronics wiring to larger industrial cables.

Advanced Control Systems: Equipped with imported electrical components and intuitive touch-screen interfaces, these machines allow for easy operation, monitoring, and adjustments. This reduces setup time and human error.

Low Noise and Maintenance: Engineered for efficiency, they produce minimal operational noise and are designed for convenient maintenance, enhancing the working environment and reducing downtime.

Eco-Friendly Design: Many bunching machines are finished with green, non-toxic paints that are both people-friendly and environmentally safe—an important consideration in modern manufacturing facilities.

Applications

Bunching machine are used extensively in industries like:

Electrical cable manufacturing

Automotive wiring production

Telecommunications

Aerospace wiring systems

In all these sectors, consistent wire bundling is crucial for ensuring signal integrity, physical durability, and ease of installation.

What Is the Bunching Process?

The bunching process is a manufacturing method used primarily in the production of electrical wires and cables, where multiple strands of conductive wire—typically copper or tinned copper—are twisted together into a single, uniform bundle. This technique enhances the mechanical strength, flexibility, and conductivity of the final wire product, making it suitable for a wide range of electrical applications, from household wiring to complex industrial cables.

Purpose of Bunching

Bunching serves several critical purposes:

Improved Flexibility: A bunch of thin strands is more flexible than a single solid wire of the same cross-sectional area. This makes the wire easier to route and install, especially in tight or mobile environments.

Enhanced Electrical Performance: Stranded wires have better current-carrying properties under dynamic conditions. While the electrical conductivity per se is not significantly increased, the wire's ability to withstand mechanical vibrations and movement without breaking improves.

Uniformity and Efficiency: Bunching ensures a consistent twist pattern and wire diameter, which is essential for maintaining quality and reliability across large batches of cable production.

How the Bunching Process Works

The bunching process begins by feeding multiple bare or tinned copper wire strands into a high-speed bunching machine. The key functions of this machine include:

Automatic Twisting: The strands are twisted together in a helical pattern. The number of twists per meter can be controlled based on application needs.

Variable Size Handling: These machines are capable of processing wires of various diameters, making them versatile across different product lines.

High-Speed Operation: Modern bunching machines are engineered for high-speed production, enabling manufacturers to meet large-scale demand efficiently.

Advanced Bunching Technology

Contemporary bunching machines are equipped with features that improve reliability and ease of use:

Imported Electrical Components: These components ensure higher precision, durability, and responsiveness, often operated via an intuitive touch screen interface.

Low Noise Operation: Designed to reduce acoustic emissions, modern bunchers create a safer and more comfortable working environment.

Eco-Friendly Design: The use of green, human-safe paint and energy-efficient components aligns with growing environmental and safety regulations.

Easy Maintenance: Simplified machine architecture allows for quick servicing and reduced downtime.

Applications of Bunched Wires

Bunched wires are ubiquitous in the electrical and electronics industries. They are used in:

Power cables

Audio/video wiring

Automotive wiring harnesses

Data transmission cables

Flexible cords for appliances

What Is the Difference Between Stranding and Bunching?

Stranding and bunching are two essential processes in wire and cable manufacturing, particularly when working with multi-strand copper or tinned wires. While both involve combining multiple individual wires into a single larger conductor, they differ significantly in structure, purpose, and method. Understanding these differences is crucial for selecting the right process depending on the application's electrical, mechanical, and production requirements.

1. Definition and Purpose

Stranding is the process of twisting multiple wire strands together in a precise geometric pattern, often following a concentric or layered structure. Its main goal is to produce a conductor with consistent mechanical properties, flexibility, and uniform electrical performance.

Bunching, on the other hand, involves randomly twisting wire strands together without a strict geometric layout. This method is faster and typically used when flexibility is more important than structural uniformity.

2. Structural Differences

Stranded Conductors

These conductors are organized in a specific pattern—usually concentric layers (e.g., 7, 19, or 37 wires). The exact alignment provides balanced electrical characteristics and improves durability under mechanical stress.

Bunched Conductors

In bunched wires, strands are twisted together in no fixed pattern. The wires can cross each other randomly within the bundle, resulting in less symmetry but greater flexibility.

3. Electrical and Mechanical Performance

Stranding

The uniform layout of stranded wires ensures consistent resistance and capacitance. This makes stranded conductors ideal for applications requiring high reliability and precise electrical characteristics, such as in power distribution or telecommunications.

Bunching

Bunched wires may show minor inconsistencies in performance due to the lack of geometric regularity. However, they are widely used in flexible cords, electronic cables, and situations where the conductor will undergo repeated bending.

4. Production Process and Equipment

Machines designed for stranding operate with controlled layering and synchronized rotation to maintain the required pattern. This makes stranding a slightly slower but more controlled process.

Bunching machines, like the one described in the provided information, are designed for speed and operational stability. They twist multiple wires at high speed with less concern for geometric arrangement. These machines accommodate wires of various sizes, use advanced electrical components for screen-based operation, and are engineered for low noise and easy maintenance.

5. Applications

Stranding is commonly used in:

Power cables

Data and communication cables

Automotive wiring where vibration resistance is key

Bunching is typically found in:

Power cords

Electronic and appliance wiring

Speaker cables

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us