Wire drawing and tube drawing are both processes used in manufacturing to produce metal products with specific shapes, sizes, and properties. Though they are similar in many respects, there are distinct differences between the two. In this article, we'll explore the processes in-depth, compare the differences, and discuss their applications.

Wire Drawing

Wire drawing is a metalworking process used to reduce the cross-sectional area of a wire or rod by pulling it through a die. It is typically used for materials such as copper, aluminum, steel, or tungsten to produce wires for various applications, including electrical, mechanical, and industrial uses.

Process Overview

Wire drawing involves the following basic steps:

Starting Material: A rod, usually made of a metal like copper, steel, or aluminum, is the starting material. This rod is heated and then passed through a series of progressively smaller dies.

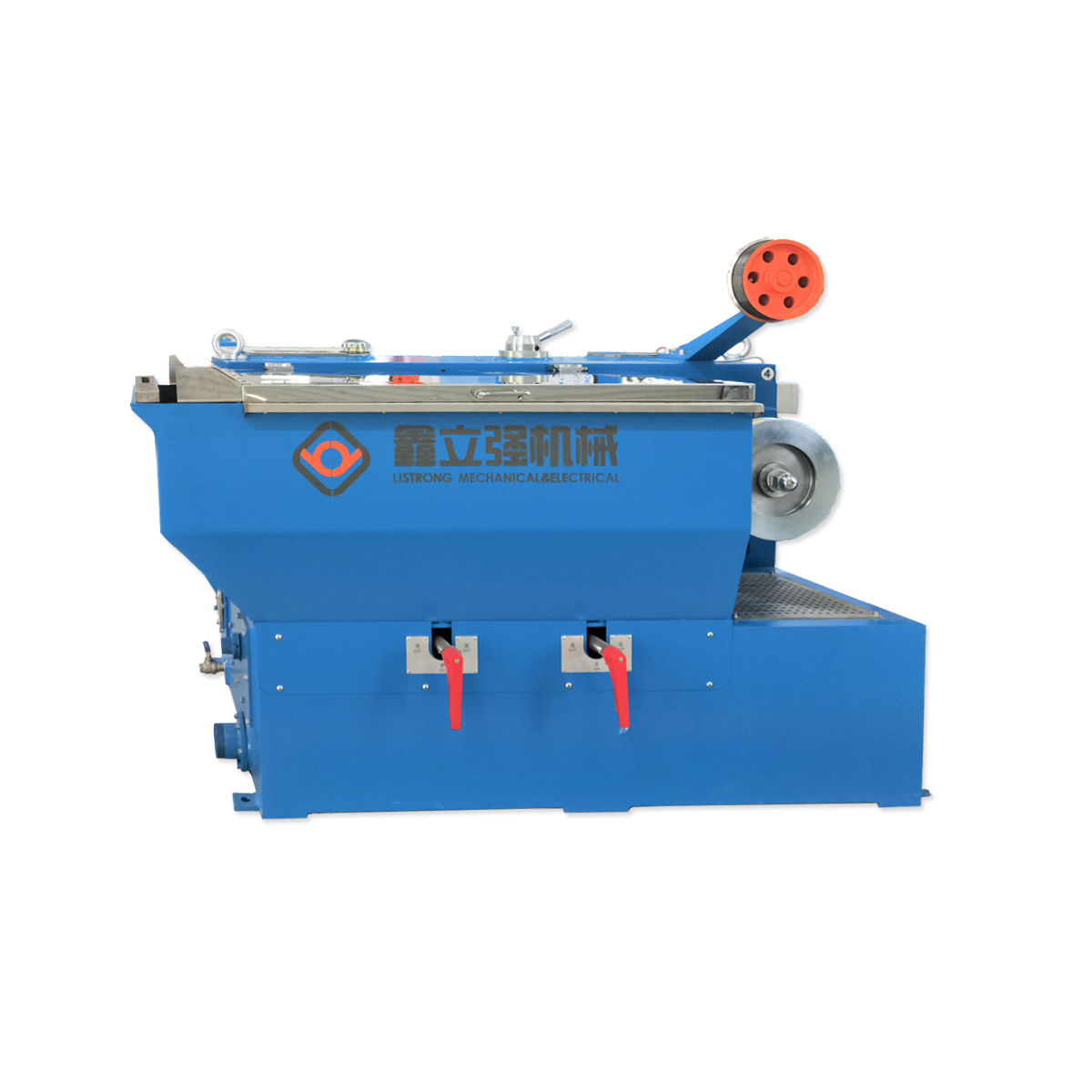

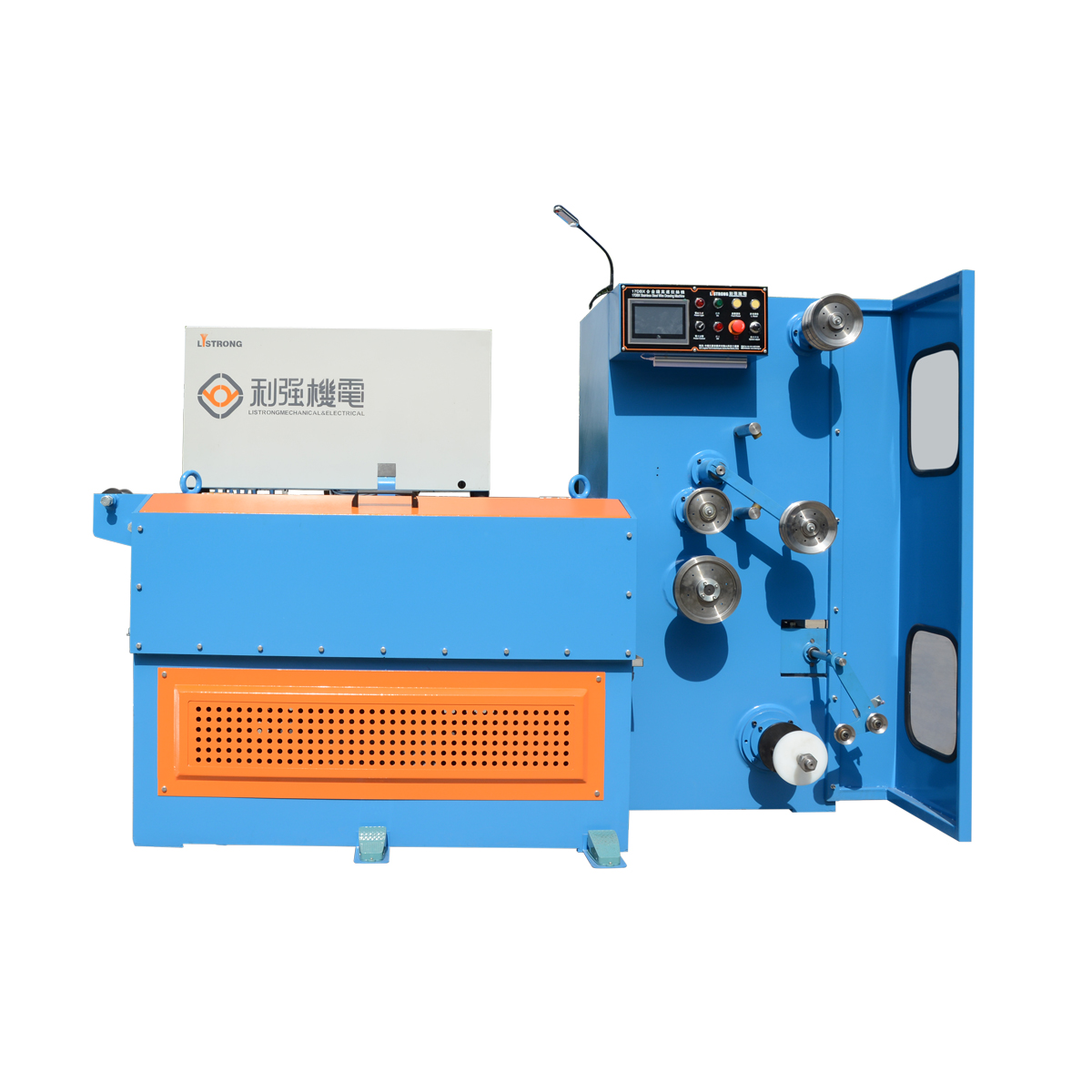

Die and Pulling: The metal is pulled through a die, which gradually reduces the wire's diameter. The process typically uses a continuous pulling mechanism, such as a capstan or a drawbench, to apply tension to the metal.

Reduction in Cross-Sectional Area: As the wire passes through each die, its diameter decreases, and its length increases. This reduction in cross-sectional area enhances the wire's strength and ductility.

Annealing: After the drawing process, the wire may undergo annealing (heating and cooling) to relieve the internal stresses and improve its ductility.

Coiling: Once the desired thickness is achieved, the wire is coiled into reels or spools, ready for further processing or use.

Key Characteristics of Wire Drawing

Material: Used for producing wires of various materials, including copper, steel, and aluminum.

Shape: Produces round wires, though oval or flat profiles can also be achieved depending on the die.

Applications: Electrical wiring, industrial cables, jewelry, springs, and more.

Strength: The wire gains increased strength as it is drawn, due to the reduction in its cross-sectional area and work hardening.

Tube Drawing

Tube drawing, as the name suggests, is a process used to reduce the diameter and wall thickness of a metal tube or hollow profile. Like wire drawing, tube drawing involves pulling the material through dies, but it differs significantly in the geometry and applications.

Process Overview

Starting Material: Tube drawing typically begins with a solid billet or tube that has an outer diameter larger than the final desired tube size. The tube is then heated and prepared for drawing.

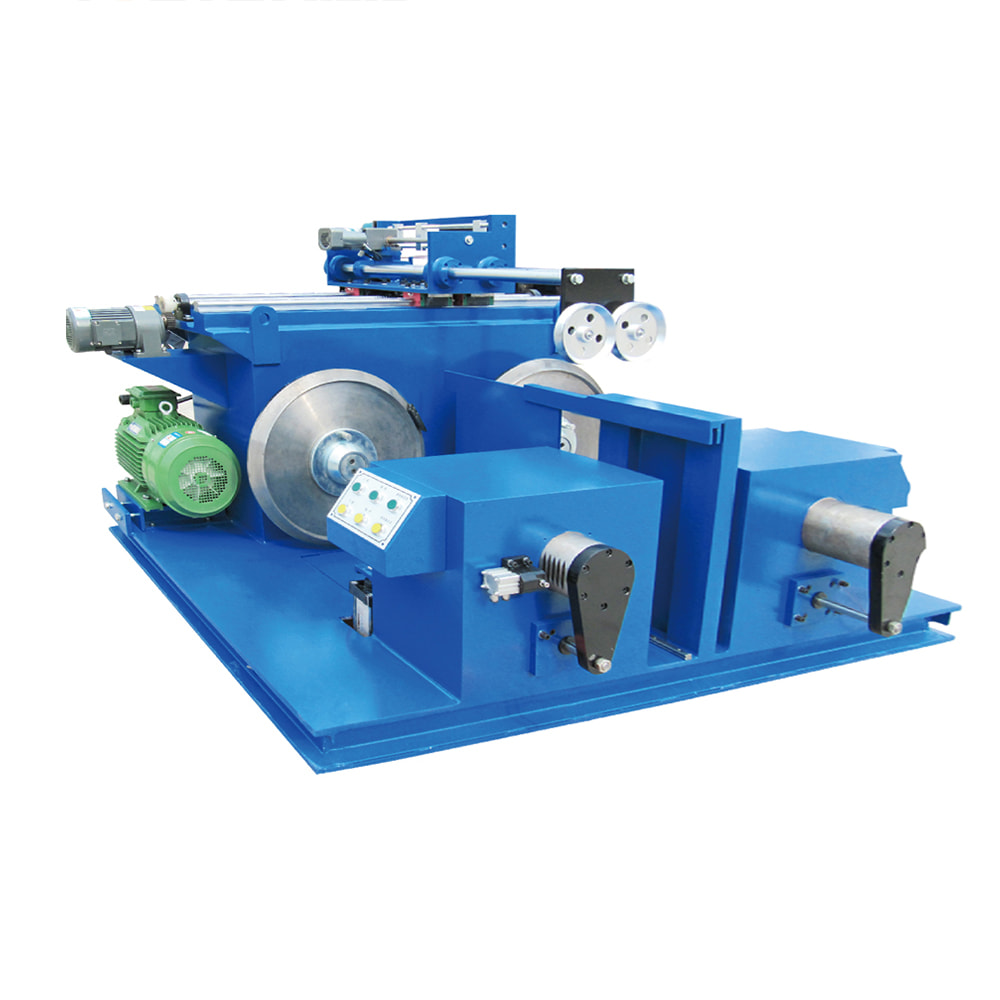

Drawing Process: In the drawing process, the tube is pulled through a die, just like wire drawing. The tube is often passed through a mandrel (a rod placed inside the tube) to prevent it from collapsing under tension. This ensures that the inner diameter of the tube remains consistent while reducing the outer diameter.

Mandrel and Die: A mandrel is used to maintain the internal diameter of the tube and prevent it from shrinking or distorting. The die reduces the outer diameter of the tube as it is pulled through.

Annealing and Stretching: Similar to wire drawing, tube drawing may also involve an annealing process to reduce internal stresses and improve ductility. In some cases, the tubes are stretched to a desired size and shape.

Cutting and Finishing: After the drawing process, the tube may be cut to length, further finished, or used in its current form.

Key Characteristics of Tube Drawing

Material: Tubes can be made from various metals such as stainless steel, copper, aluminum, or titanium.

Shape: The primary output is a hollow tube with a precise inner and outer diameter. The shape can be round, square, rectangular, or custom shapes based on the die.

Applications: Used in manufacturing automotive parts, medical devices, aerospace components, fluid transport systems, and heat exchangers.

Strength: Tube drawing also increases the strength of the tube, particularly in terms of tensile strength, while maintaining or improving the tube's structural integrity.

Key Differences Between Wire Drawing and Tube Drawing

Material Shape:

Wire Drawing: Focuses on creating a solid, cylindrical shape, typically producing round wire.

Tube Drawing: Deals with hollow profiles (tubes) and focuses on reducing both the outer diameter and wall thickness.

Cross-Section:

Wire Drawing: The cross-section is solid and typically round, although other profiles can be made.

Tube Drawing: The cross-section is hollow, with a precise inner and outer diameter, making it suitable for applications requiring fluid or gas transportation.

Tools Used:

Wire Drawing: Primarily uses a series of dies through which the wire is drawn. The dies are often smaller than the original diameter.

Tube Drawing: Uses both a die and a mandrel. The mandrel helps control the internal diameter of the tube while the die reduces the outer diameter.

Material Flow:

Wire Drawing: The metal is compressed and elongated, and its cross-sectional area reduces as it passes through the die.

Tube Drawing: The material is drawn, but because it is hollow, there is an additional concern with maintaining the internal diameter and preventing collapse during drawing.

Applications:

Wire Drawing: Primarily used for creating electrical wires, cables, and other industrial wire products.

Tube Drawing: Used for making tubes or pipes that are used in industries such as aerospace, automotive, medical, and fluid transport.

Applications and Industries

Wire Drawing:

Electrical Industry: Wire drawing is crucial for producing electrical cables that conduct power. Copper and aluminum are the most commonly used materials in electrical wire manufacturing.

Automotive: Wire is used in the production of components like springs, cables, and connectors.

Construction: Steel wire is used for reinforcing concrete in construction.

Tube Drawing:

Automotive: Tube drawing is essential in the automotive industry for producing pipes, exhaust systems, and hydraulic components.

Medical Devices: Stainless steel tubes are used in medical instruments, stents, and needles.

Aerospace: Tubes are used in fuel systems, hydraulic systems, and other aerospace applications where high strength and resistance to pressure are needed.

Fluid Transport: Tubes are used for transporting liquids or gases, and tube drawing ensures they meet the required pressure and diameter specifications.

Conclusion

While wire drawing and tube drawing are both methods of reducing the size of a metal by pulling it through a die, the key difference lies in the product's geometry. Wire drawing focuses on solid wires with small diameters, while tube drawing is used to create hollow tubes with precise inner and outer diameters. Both processes enhance the material's strength and ductility and serve vital roles across various industries.

In both cases, the final product must meet strict quality control standards, ensuring that the material properties, including strength, flexibility, and dimensional accuracy, are optimized for the specific application. The choice of process depends on the end-use requirements—whether it's a flexible wire for electrical connections or a robust tube for carrying fluids under pressure.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us