Selecting the right Wire Annealing Machine is one of the most important decisions a manufacturer can make when setting up or upgrading a production line. The machine directly affects not just the immediate output but also the long-term quality, efficiency, and profitability of the operation. With so many models and specifications available, decision-making can feel overwhelming, but a closer look at a few critical factors can provide clarity and confidence.

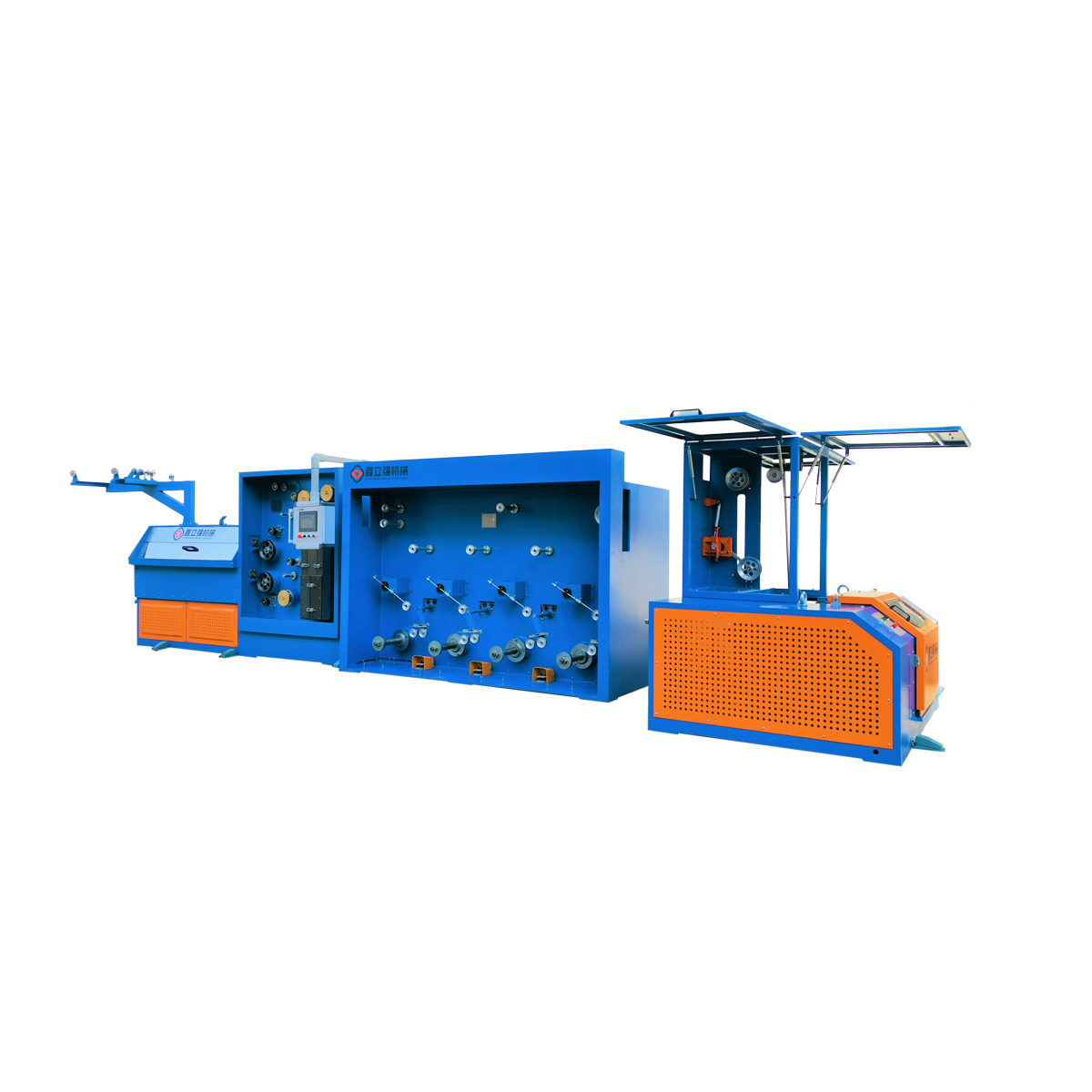

The first consideration should always be the type of wire and its intended application. Copper, aluminum, and steel wires all have different annealing requirements in terms of heating cycles and temperature precision. A Wire Annealing Machine that is not matched to the material can lead to inconsistent results, increased scrap, and unnecessary downtime. This is why leading manufacturers often provide machine customization, ensuring that the equipment is designed with the specific wire material in mind.

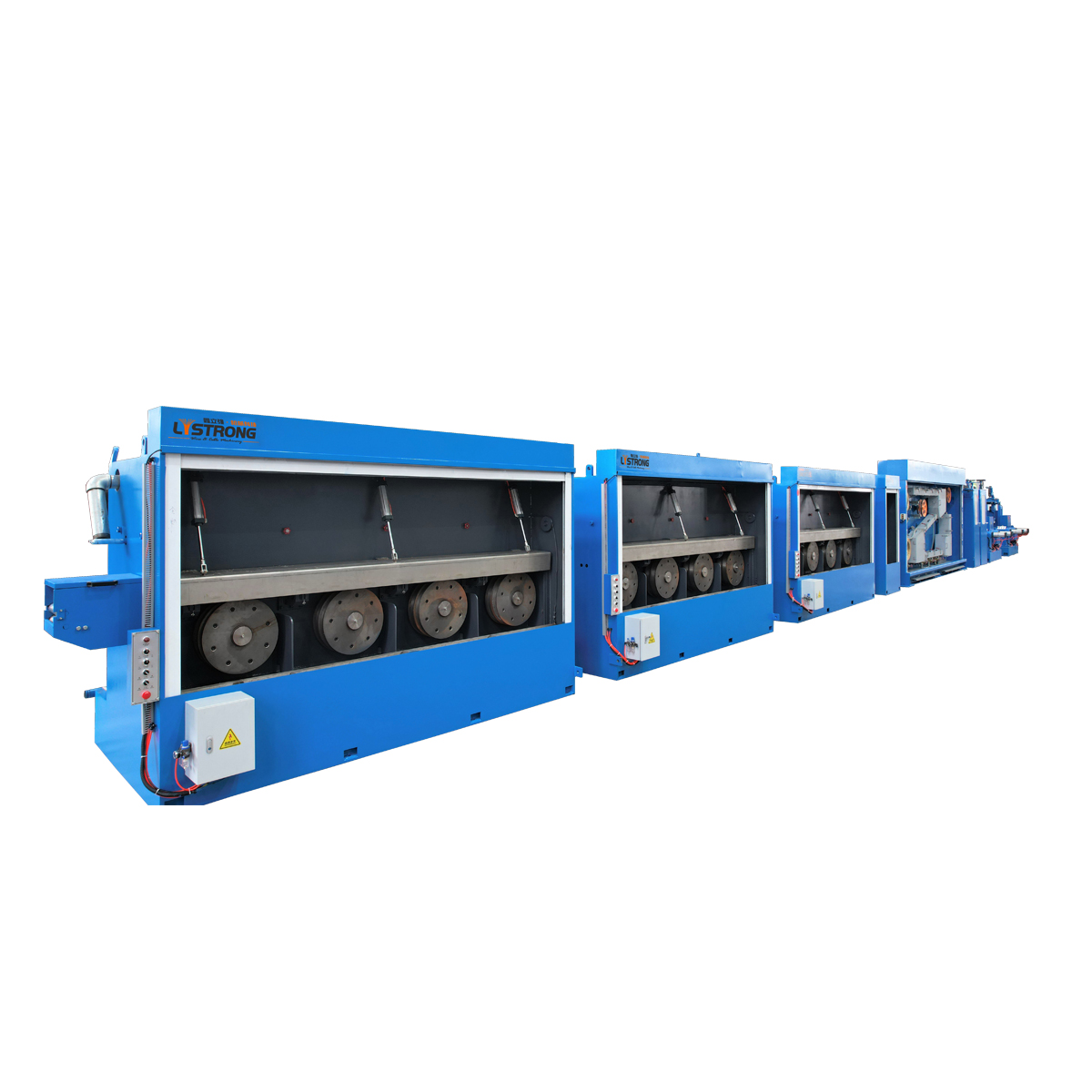

Production volume is another key factor that should influence your choice. High-output environments, such as those in large-scale electrical or construction industries, benefit most from continuous annealing machines that allow for uninterrupted processing. On the other hand, smaller manufacturers or those handling a wider variety of wire types may prefer batch-type machines, which offer greater flexibility without compromising on quality. Investing in a machine that aligns with your production scale ensures efficiency without overextending resources.

Energy efficiency is also gaining attention as manufacturers look for ways to lower costs and meet sustainability goals. A modern Wire Annealing Machine with optimized heating technology can significantly reduce power consumption while maintaining uniform results. Over time, these savings add up to a meaningful reduction in operating expenses. Beyond cost savings, energy-efficient machines can enhance a manufacturer’s reputation in industries that value environmental responsibility.

Process consistency is critical when it comes to wire annealing, as even small variations in heating can lead to brittle or unevenly softened wires. Machines with advanced control systems and real-time monitoring ensure that each batch or continuous run delivers wires with uniform properties. This translates directly into stronger, more reliable products and fewer customer complaints or returns. Manufacturers looking to compete in international markets should see this as a non-negotiable factor when choosing equipment.

Maintenance and after-sales support are equally important considerations. A Wire Annealing Machine is a long-term investment, and reliable access to spare parts, technical guidance, and timely service ensures that it continues to operate at peak performance for years. Buyers should look beyond the initial purchase price and carefully evaluate the reputation of the supplier in providing comprehensive service packages. This is often the difference between equipment that pays for itself quickly and one that becomes a burden.

Compliance with international safety and quality standards should not be overlooked. Machines that are built to meet ISO or CE certifications, for example, guarantee adherence to strict safety and performance benchmarks. For exporters or companies working with global partners, this compliance is not just a bonus but often a requirement. A Wire Annealing Machine that meets such standards simplifies trade and inspires confidence among clients.

Another factor that often gets underestimated is scalability. Many businesses grow faster than expected, and choosing a machine that can handle increased output or accommodate future upgrades can prevent the need for premature replacement. A forward-thinking investment in a versatile Wire Annealing Machine can protect a company from unexpected bottlenecks as demand rises.

Price naturally plays a role in the decision-making process, but the cheapest option is rarely the best in the long term. The real value lies in the balance between cost, performance, and durability. Manufacturers should conduct a thorough return-on-investment analysis, considering not only the purchase price but also the savings achieved through efficiency, reduced scrap, and lower maintenance needs. A well-chosen machine often pays for itself sooner than expected.

Ultimately, the right Wire Annealing Machine is not just a piece of equipment; it is a partner in production. By carefully evaluating material compatibility, production scale, efficiency, consistency, service support, safety compliance, scalability, and overall value, manufacturers can make an informed choice that secures long-term growth. As an experienced supplier in this industry, we understand that every customer’s needs are unique, which is why we provide tailored solutions designed to help you achieve the highest standards of quality and reliability in wire manufacturing.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us