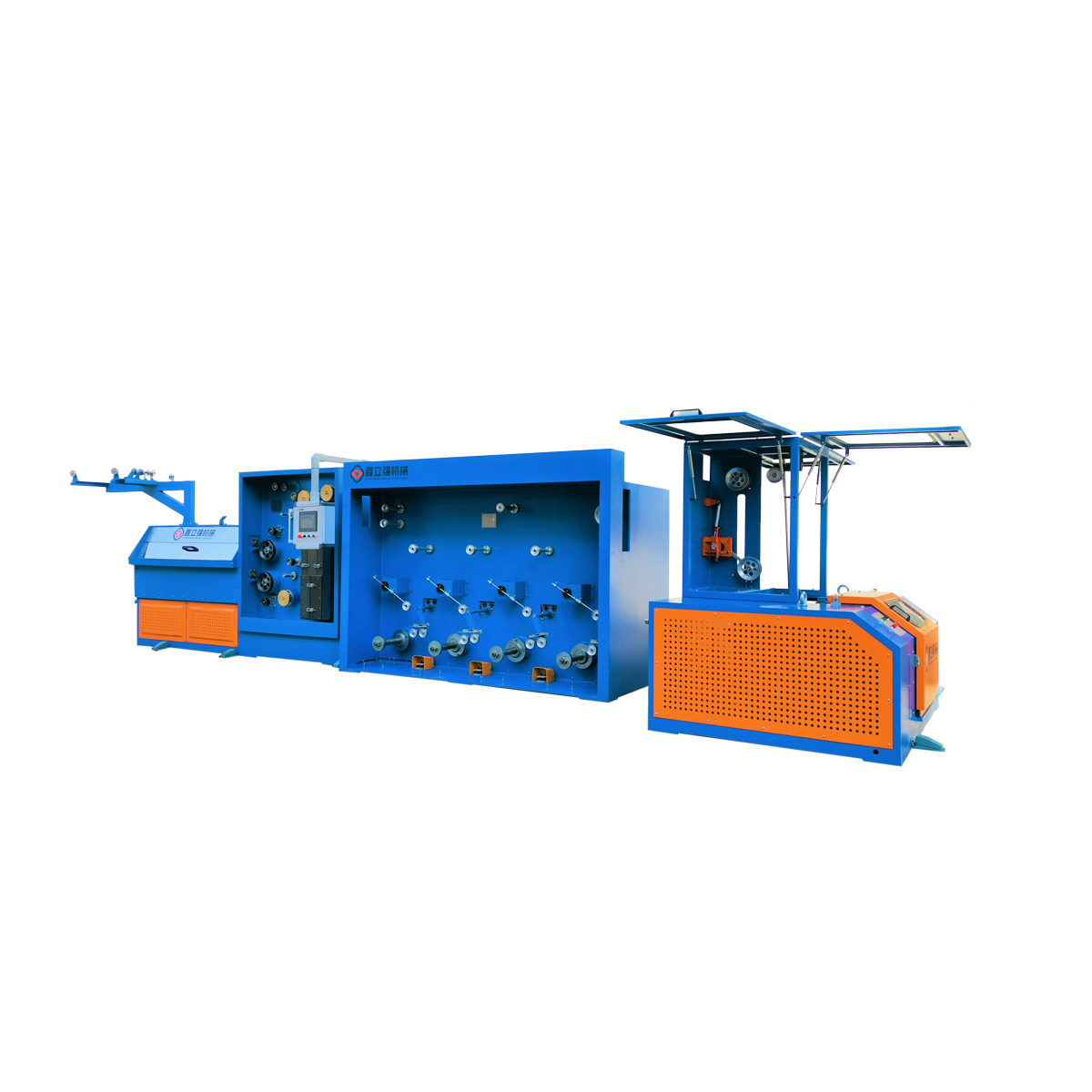

When it comes to Brass Wire Drawing Machines, the structural design of the machine body plays a critical role in performance, durability, and maintenance. One of the key choices manufacturers face is between an integrated cast iron body and a modular frame structure. Our experience as a leading manufacturer has shown that adopting a cast iron integrated forming for the machine body brings numerous advantages that directly impact wire quality and operational efficiency, making it a preferred solution in modern brass wire production.

Cast iron is renowned for its excellent vibration damping properties, and this characteristic is vital in wire drawing applications where precision and surface finish are paramount. An integrated cast iron body significantly reduces vibrations generated during the drawing process, which prevents wire deformation and ensures consistent dimensional accuracy. This rigidity helps maintain the tight tolerances required for brass wire used in demanding industries, such as electronics and EDM wire production.

Beyond vibration control, the integrated casting approach creates a unified frame with fewer joints and welds, which enhances the overall strength and stability of the machine. Unlike modular frames that rely on bolted or welded connections, the cast iron structure resists fatigue and deformation even under high mechanical stress and continuous operation. This structural integrity means less frequent recalibration, reduced maintenance downtime, and a longer service life for the machine — all crucial factors for businesses aiming to optimize production costs.

Another important aspect is how the integrated cast iron body supports the alignment of critical components such as the wire drawing dies and tension control systems. Precise alignment is essential for uniform wire diameter and surface quality. Our Brass Wire Drawing Machines leverage this solid foundation to maintain exact positioning over long production runs, which helps minimize scrap rates and rework, delivering better ROI for our customers.

From a maintenance perspective, machines with an integrated cast iron body often allow for more straightforward servicing because the rigid structure minimizes misalignment issues that could otherwise arise during routine maintenance or part replacement. This contributes to smoother belt transmission performance and reduces wear on moving parts, meaning less frequent interventions and lower operating costs.

Choosing a Brass Wire Drawing Machine with an integrated cast iron body is not only about robustness; it reflects a commitment to manufacturing excellence and precision engineering. As a trusted supplier, we design our machines to provide consistent, high-quality output, tailored to meet the stringent requirements of brass wire production in various industrial applications. This structural advantage, combined with our advanced automation features, offers a compelling solution for manufacturers seeking both reliability and efficiency.

In conclusion, the integrated cast iron forming of the machine body is a cornerstone of superior Brass Wire Drawing Machines, delivering unmatched stability, vibration reduction, and long-term durability. For businesses serious about optimizing brass wire production, investing in a machine with this design ensures better product quality, lower maintenance costs, and enhanced operational reliability — benefits that truly set your production line apart.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us