In the ever-growing electrical and telecommunications industries, the production of cables is critical to ensure reliability, durability, and efficient transmission of power or data. A wire cable bunching machine plays a pivotal role in modern cable manufacturing by effectively bundling and twisting wires to create uniform and high-quality cables. This article delves into the inner workings of wire cable bunching machines, the different types available, their applications, and how they contribute to the production process.

What is a Wire Cable Bunching Machine?

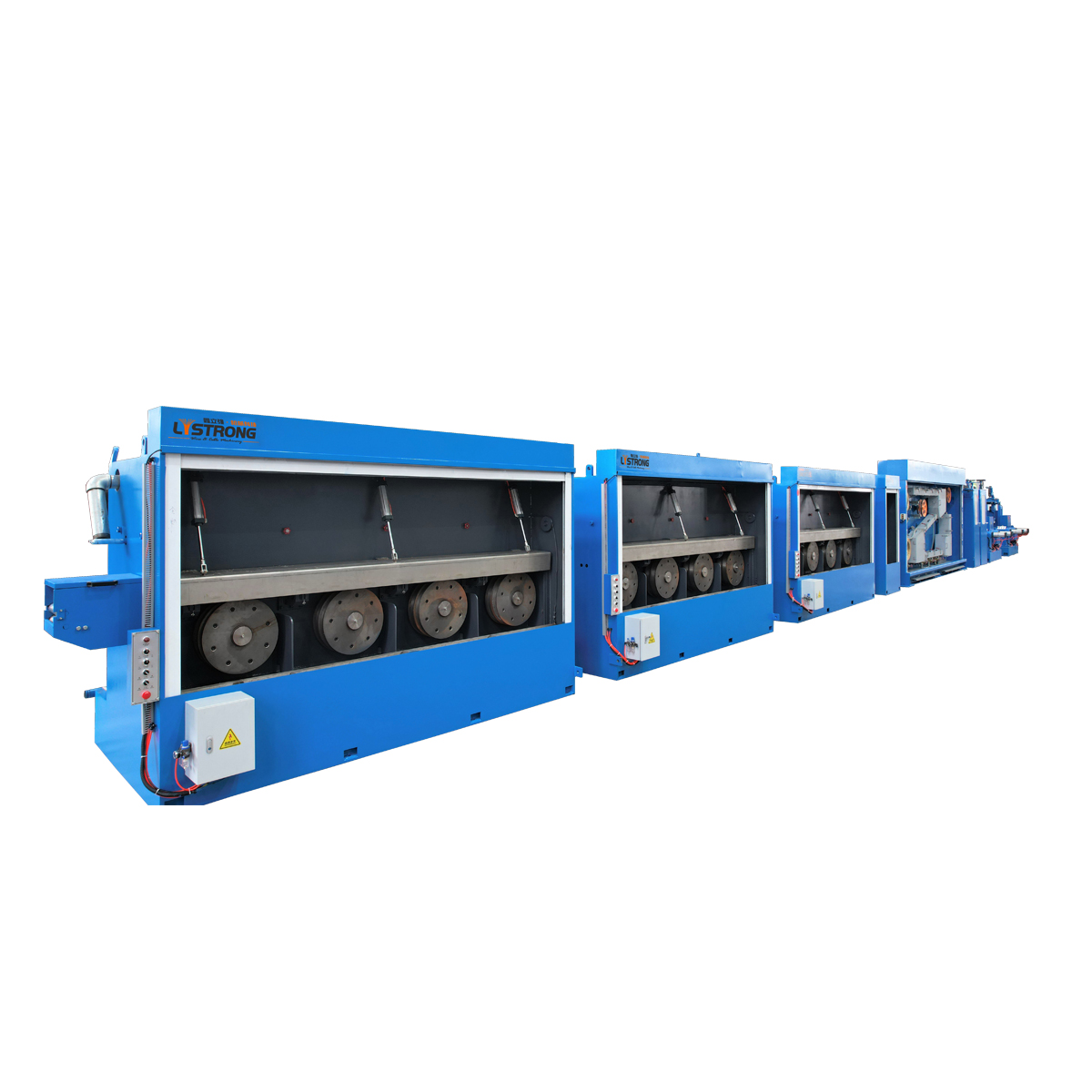

A Wire Cable Bunching Machine is an industrial equipment designed to group or bunch multiple strands of wire together to form a twisted or parallel bundle. These machines are extensively used in the production of electrical wires and cables, where several smaller conductors are required to be grouped together to form a larger cable. The bunching process involves twisting the wires tightly, which ensures a solid connection and prevents them from unwinding during further processing, such as insulation or sheathing.

Typically, a bunching machine consists of several components, including a capstan (drum), bunching heads, and a wire guide system. The wires are fed into the machine, which then twists them according to the specified design parameters.

How Does a Wire Cable Bunching Machine Work?

The working principle of a wire cable bunching machine can be broken down into several steps:

Wire Feeding:

The machine receives multiple strands of wire through a feeding mechanism, which ensures that the wires are fed into the system at a consistent rate. The feed can either be manual or automatic, depending on the design of the machine.

Twisting or Bunching:

The wires are passed through a bunching head, which is typically equipped with rollers or spools that twist the wires together. The twisting process is performed under controlled tension to ensure uniformity and prevent wire breakage.

Output Spool:

After the bunching process, the twisted wires are collected onto an output spool or reel. These bundled wires are now ready for further processing, such as insulation or sheathing, or can be used as is, depending on the final application.

Adjustable Parameters:

Modern wire bunching machines allow manufacturers to adjust key parameters such as wire twist angle, bunching speed, and tension. This flexibility is essential for producing a wide variety of cables, from simple electrical wiring to complex multi-core cables.

Types of Wire Cable Bunching Machines

Wire cable bunching machines come in several configurations to cater to different manufacturing requirements. The main types are:

Single Twist Bunching Machine:

As the name suggests, this machine performs a single twist per wire. It is typically used for less complex wire bunching tasks where simple twisted conductors are needed. Single twist bunching machines are widely used in the production of power cables and low-voltage wiring.

Double Twist Bunching Machine:

In double twist machines, two wires are twisted simultaneously in opposite directions, resulting in more compact and tightly twisted cables. This type is used when greater mechanical strength and insulation are required.

High-Speed Bunching Machine:

High-speed machines are designed to operate at greater speeds while maintaining precision in the twisting process. They are ideal for large-scale production runs of cables where time efficiency is a priority.

Multi-Capstan Bunching Machine:

Multi-capstan bunching machines are used to twist multiple wires simultaneously. This setup is ideal for high-volume production of multi-conductor cables. The use of multiple capstans also ensures better control over the tension, preventing the wire from becoming slack or twisted unevenly.

Applications of Wire Cable Bunching Machines

Wire cable bunching machines find widespread use across various industries where cables and wires are essential components. Some of the most common applications include:

Electrical Wiring:

Wire cable bunching machines are primarily used to produce electrical cables for homes, buildings, and industrial applications. These cables are used to transmit power safely and efficiently.

Telecommunications:

For telecommunications cables, where high-quality data transmission is crucial, bunching machines are used to ensure consistent wire twists, which prevent signal interference.

Automotive Industry:

The automotive sector uses complex cables with multiple conductors for powering electronic components like lighting systems, infotainment, and sensors. Bunching machines help in the precise manufacture of these cables.

Industrial Machinery:

Wire bundles are commonly found in industrial machinery, automation systems, and control panels. A bunching machine ensures that these wires are appropriately twisted to handle high mechanical stress.

Power Transmission:

For overhead and underground power transmission, high-voltage cables are often produced with the help of bunching machines to ensure they are robust and durable enough to handle extreme conditions.

Benefits of Using a Wire Cable Bunching Machine

The integration of wire bunching machines into the manufacturing process offers numerous advantages:

Consistency and Precision:

Bunching machines provide uniform twisting, ensuring high-quality cables that meet industry standards for performance and durability.

Increased Efficiency:

These machines operate at high speeds, enabling manufacturers to produce large quantities of cables in a short amount of time, which reduces production costs.

Improved Quality Control:

With precise control over parameters such as twist tension and speed, manufacturers can minimize defects and improve the overall quality of the cables.

Flexibility in Design:

Wire bunching machines allow manufacturers to tailor the bunching process to create cables of varying lengths, sizes, and wire configurations. This flexibility ensures the ability to meet a diverse range of customer needs.

Automation and Reduced Labor Costs:

Many modern bunching machines are automated, reducing the need for manual labor and allowing operators to focus on overseeing the overall production process.

Challenges and Considerations

While wire cable bunching machines bring many benefits, there are also challenges that manufacturers need to consider:

Maintenance Requirements:

These machines require regular maintenance to ensure optimal performance. Lubrication, cleaning, and component inspections must be carried out to prevent malfunctions.

Initial Investment:

High-quality bunching machines can be a significant capital investment, especially for high-speed or multi-capstan machines. However, the long-term cost benefits often outweigh the initial expense.

Wire Compatibility:

The machine must be compatible with the specific wire materials used in production, as some wires may be more prone to breakage or require different tension settings.

Conclusion

Wire cable bunching machines are essential equipment in the cable manufacturing process, streamlining the creation of robust, high-quality cables that meet the demands of various industries. Whether for power transmission, telecommunications, or automotive applications, these machines offer precision, efficiency, and flexibility that manufacturers rely on to produce cables at scale. With advancements in technology, wire bunching machines continue to evolve, allowing for even faster, more cost-effective production while maintaining high standards of quality.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us