Introduction to Fine Steel Wire Drawing and Pulling System Line

The fine steel wire drawing and pulling system line is a crucial component in the manufacturing process of high-quality steel wires, playing a key role in industries such as construction, automotive, electrical, and telecommunications. This system involves a series of mechanical and electrical processes designed to reduce the diameter of steel rods or coils, transforming them into fine steel wires with precise dimensions and surface finish. The efficiency and precision of the drawing and pulling system directly impact the quality and performance of the final product.

Understanding the Fine Steel Wire Drawing Process

Wire drawing is a metalworking process in which a wire is pulled through a series of dies to reduce its diameter. The system used in fine steel wire drawing incorporates multiple stages, each crucial for achieving the desired properties of the wire, including high tensile strength, flexibility, and smooth surface texture. The process generally involves the following steps:

1. Preparation of Raw Material

The first step is selecting and preparing high-quality steel rods or coils, which serve as the raw material for the wire drawing process. These materials must meet specific chemical and mechanical properties to ensure the resulting wire can withstand stress, corrosion, and environmental conditions.

2. Initial Reduction

The raw steel is initially reduced in diameter by passing through a set of large dies. This step may be repeated several times to progressively decrease the diameter of the steel while increasing its length. This process is critical to ensure the wire maintains uniformity and consistency throughout.

3. Intermediate Drawing and Annealing

At intermediate stages, the wire may be annealed—heated and cooled—to relieve internal stresses and improve ductility. Annealing ensures the wire retains its flexibility and reduces the risk of cracking during subsequent drawing steps. The wire is then pulled through finer dies for further reduction.

4. Final Drawing

The final drawing stage involves pulling the wire through the smallest die in the system to achieve the desired diameter. The wire's surface quality and mechanical properties, such as tensile strength, are carefully controlled at this stage.

5. Winding and Coiling

After the wire reaches the desired size, it is wound onto reels or spools for further processing or shipment. This stage is essential for preparing the wire for use in various applications.

The Pulling System: Mechanism and Role

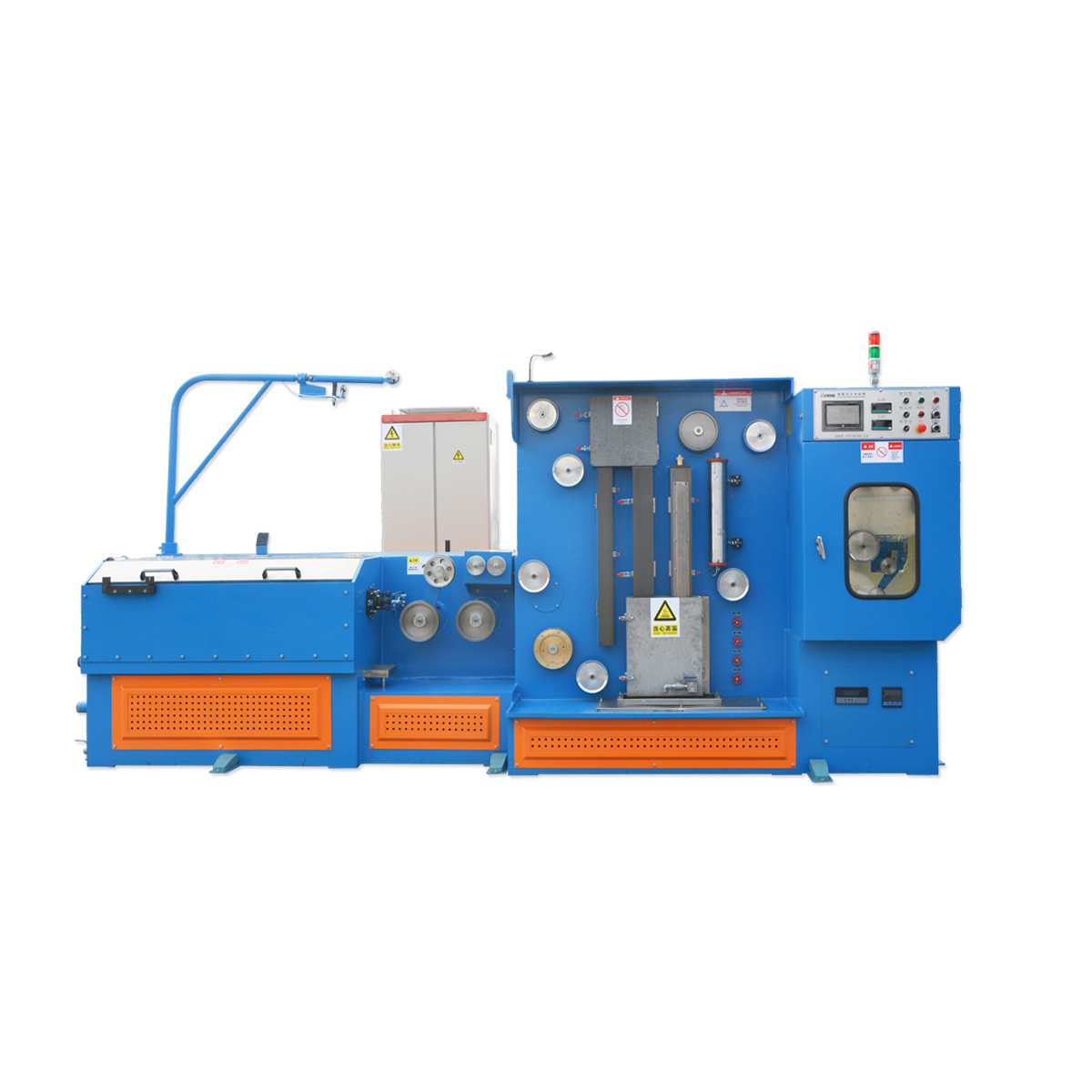

The pulling system plays a critical role in the wire drawing process by applying continuous tension to the wire as it moves through the dies. It ensures smooth operation, precise control over the drawing speed, and uniform tension across all stages. Typically, the pulling system consists of:

Capstan Rolls: These are large rotating rollers that grip the wire and pull it through the dies. The capstan rolls ensure a consistent feed rate and provide the necessary force to reduce the wire's diameter without causing deformation or breakage.

Tension Control: Tension is carefully monitored and adjusted using advanced control systems, such as load cells and motorized winches. Maintaining the correct tension is essential for preventing wire breakage, reducing wear on the dies, and achieving the desired surface quality.

Drive Motors: Electric motors drive the pulling system, allowing for variable speeds and efficient operation across all stages of the drawing process.

Types of Fine Steel Wire Drawing Systems

There are various configurations of fine steel wire drawing systems, including:

1. Single-Block Drawing System

In a single-block drawing system, the wire passes through a single block containing multiple dies in sequence. This is a more compact setup suitable for producing smaller quantities of wire with uniform quality.

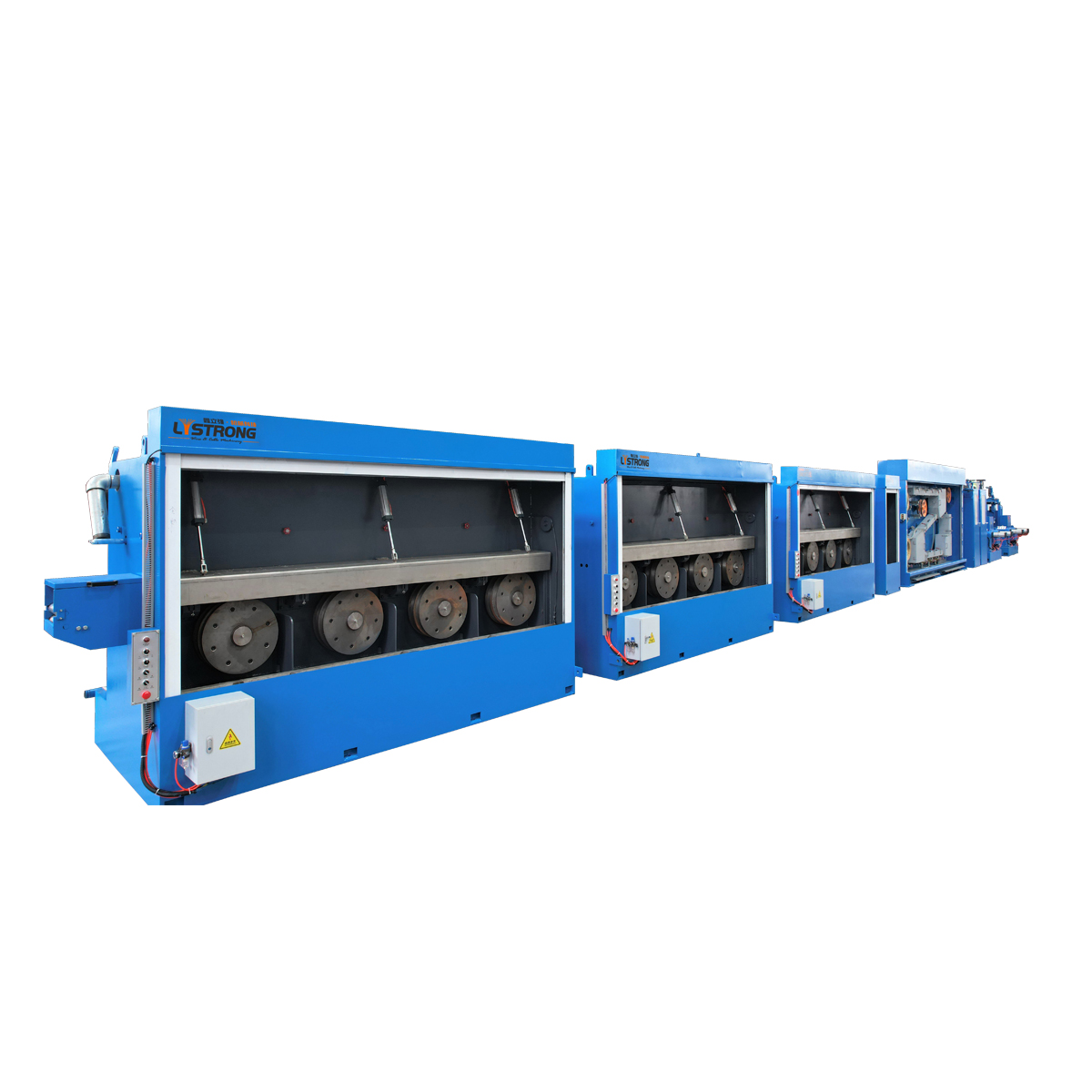

2. Multi-Block Drawing System

This system is used for larger-scale production and involves multiple blocks of dies arranged in a series. The wire is progressively drawn through each block, and each block typically features its own pulling system. Multi-block systems are more complex but offer higher productivity and better control over the wire's properties.

3. Rotary Drum Drawing System

In this system, the wire is wound onto a rotating drum, which pulls the wire through the dies. This configuration is particularly suitable for drawing fine wires used in applications requiring high flexibility and precision.

Applications of Fine Steel Wire Drawing and Pulling Systems

Fine steel wire drawing and pulling systems are used in various industries due to their ability to produce high-quality wires that meet specific performance requirements. Some key applications include:

1. Construction

Fine steel wires are widely used in the construction industry, particularly in reinforcing steel bars (rebar) for concrete structures. These wires are critical for providing strength and durability in construction materials such as cables, meshes, and wire ropes.

2. Automotive Industry

The automotive industry relies on fine steel wires for various components, including springs, cables, and wiring for electrical systems. The precision and strength of the wires ensure the safe and reliable operation of these components.

3. Electrical and Telecommunications

Fine steel wires are essential in the electrical and telecommunications sectors, where they are used in cables and wiring for communication networks and power transmission lines. The wires must exhibit excellent conductivity, flexibility, and resistance to corrosion.

4. Medical Applications

In the medical field, fine steel wires are used for surgical instruments, medical device components, and orthodontic wires. The wires' biocompatibility, strength, and flexibility make them ideal for these critical applications.

Key Advantages of Fine Steel Wire Drawing Systems

Precision: Modern wire drawing and pulling systems allow for highly accurate control over the wire’s diameter, surface finish, and tensile strength.

Efficiency: Automated systems enable faster production times, reducing costs while maintaining high-quality standards.

Versatility: The systems can be adjusted to produce wires of varying diameters, making them suitable for a wide range of applications.

Customization: With advancements in technology, manufacturers can now customize wire properties such as tensile strength, surface finish, and coating to meet specific requirements.

Technological Advancements in Wire Drawing and Pulling Systems

Recent innovations in wire drawing and pulling systems have significantly improved their efficiency and capabilities. Key advancements include:

1. Automation and Smart Controls

Advanced automation and smart control systems allow for real-time monitoring and adjustment of parameters such as drawing speed, tension, and motor torque. These systems enable better process optimization and reduce the risk of human error.

2. Multi-Roll Technology

Some advanced systems now use multi-roll drawing, where the wire is pulled by multiple rollers rather than just one capstan. This technology reduces the tension on the wire and ensures smoother drawing, improving overall wire quality.

3. Energy-Efficient Systems

With energy consumption being a major concern in the steel industry, manufacturers are adopting energy-efficient systems that reduce the overall environmental impact while maintaining high production standards.

Conclusion

Fine steel wire drawing and pulling systems are integral to producing high-quality steel wires used in numerous industries. The precision, efficiency, and customization capabilities of modern systems ensure the production of wires with superior strength, flexibility, and surface finish. With ongoing technological advancements, these systems continue to evolve, meeting the growing demands of various industrial sectors and driving innovation in wire production.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us