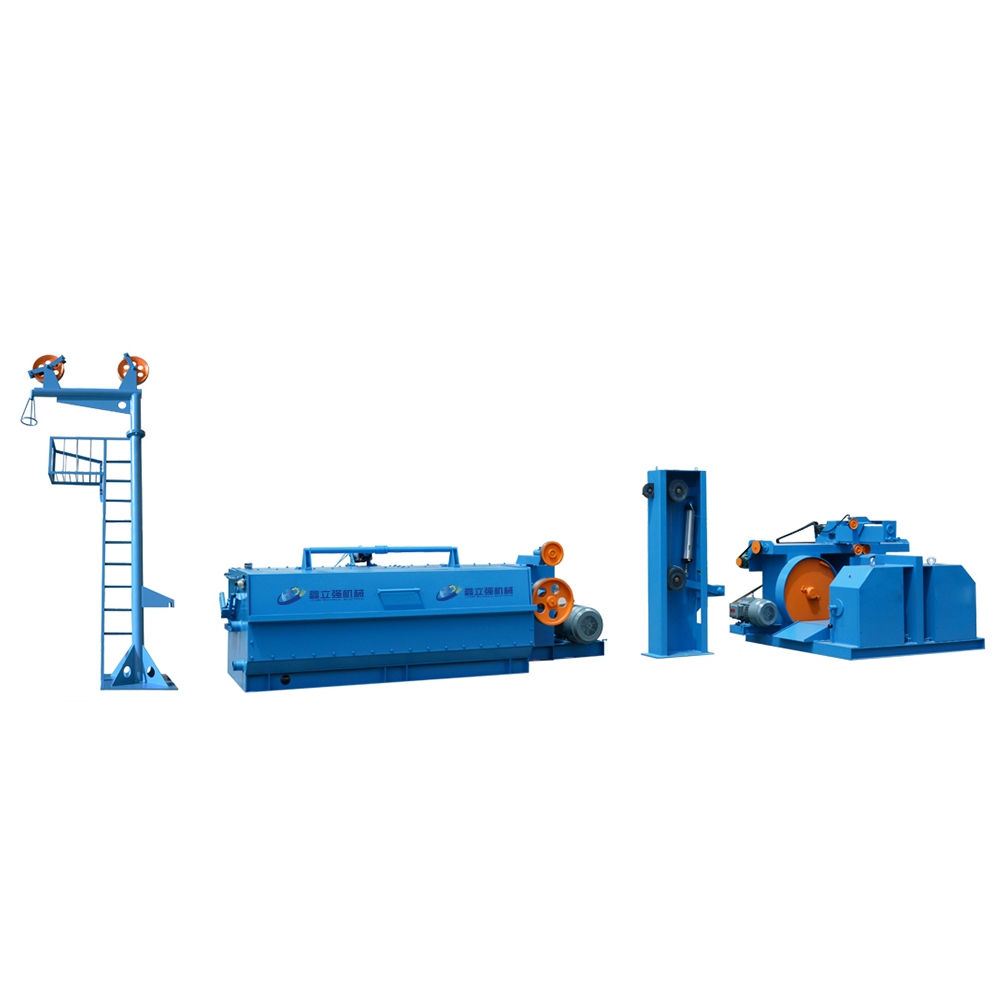

9DS Medium Copper wire drawing machine system line

Cat:Copper Wire Drawing Machines

This type of wire drawing machine is a high-speed model meticulously developed, designed, and manufactured after assimilating advanced foreign technol...

See DetailsWhen it comes to the efficiency and reliability of Aluminum Wire Rod Breakdown Machines, one crucial aspect that often stands out is the belt transmission system. Unlike traditional gear or chain-based systems, belt transmission offers several key advantages that can significantly improve the performance of wire drawing operations. As a manufacturer and supplier of high-quality aluminum wire rod breakdown machines, we recognize how this mechanism plays a vital role in not only reducing operational noise but also in enhancing the machine’s longevity and ease of maintenance.

Belt transmission operates on a simple yet effective principle, where power is transmitted from one pulley to another via a belt. This type of system offers several advantages over other transmission methods, primarily due to its quieter operation. Aluminum wire rod breakdown machines equipped with belt-driven mechanisms generate much less noise compared to their gear or chain counterparts. This is a significant factor in improving the working environment in a production facility, where reducing noise levels can lead to higher worker comfort and better overall productivity.

In addition to noise reduction, belt transmission systems are known for their efficiency in power distribution. The continuous, smooth power transfer through belts minimizes energy loss, making the machine run more efficiently. This is a key benefit for manufacturers looking to lower operational costs, as energy efficiency directly impacts electricity consumption. By utilizing aluminum wire rod breakdown machines with belt transmissions, businesses can ensure a more eco-friendly and cost-effective operation, which is essential in today’s competitive manufacturing environment.

Another important advantage of belt-driven machines is the ease of maintenance. Unlike gears, which require regular lubrication and tend to wear down over time, belts are simple to inspect and replace. Maintenance teams can easily spot signs of wear and replace belts without significant downtime, ensuring that the production process remains uninterrupted. This simplicity in maintenance makes the aluminum wire rod breakdown machine a more attractive investment for businesses aiming to reduce long-term operational costs.

The low-maintenance nature of belt transmission also contributes to the overall durability of the machine. With fewer moving parts subject to wear, the system can withstand long periods of operation without frequent repairs. In industries where uptime is critical, having a machine that runs smoothly with minimal interruptions is invaluable. This is especially true for aluminum wire drawing processes, where consistent quality and performance are paramount for producing high-grade wire for various applications.

In terms of precision, the belt transmission system in Aluminum Wire Rod Breakdown Machines ensures smooth and consistent drawing speeds. This translates to uniform wire thickness and higher-quality end products. The stable transmission of power helps maintain the machine’s performance, ensuring that each wire drawn is within the specified tolerance levels, which is essential for industries like automotive, electrical, and construction, where precise wire dimensions are required.

Lastly, a belt transmission system also helps reduce vibrations, which are often an issue with gear-driven machines. Reduced vibrations not only contribute to a quieter work environment but also extend the machine's lifespan by minimizing stress on internal components. For manufacturers looking for an optimal balance of performance, cost-efficiency, and reliability, aluminum wire rod breakdown machines with belt transmissions offer a compelling solution that meets the demands of modern production.

Overall, the integration of a belt transmission system in aluminum wire rod breakdown machines is a game-changer for manufacturers seeking to improve machine performance while reducing noise, maintenance, and operational costs. By choosing a machine that features this advanced transmission technology, businesses can enhance their production processes, increase energy efficiency, and ultimately produce higher-quality aluminum wire products with greater consistency and less downtime.

Contact Us