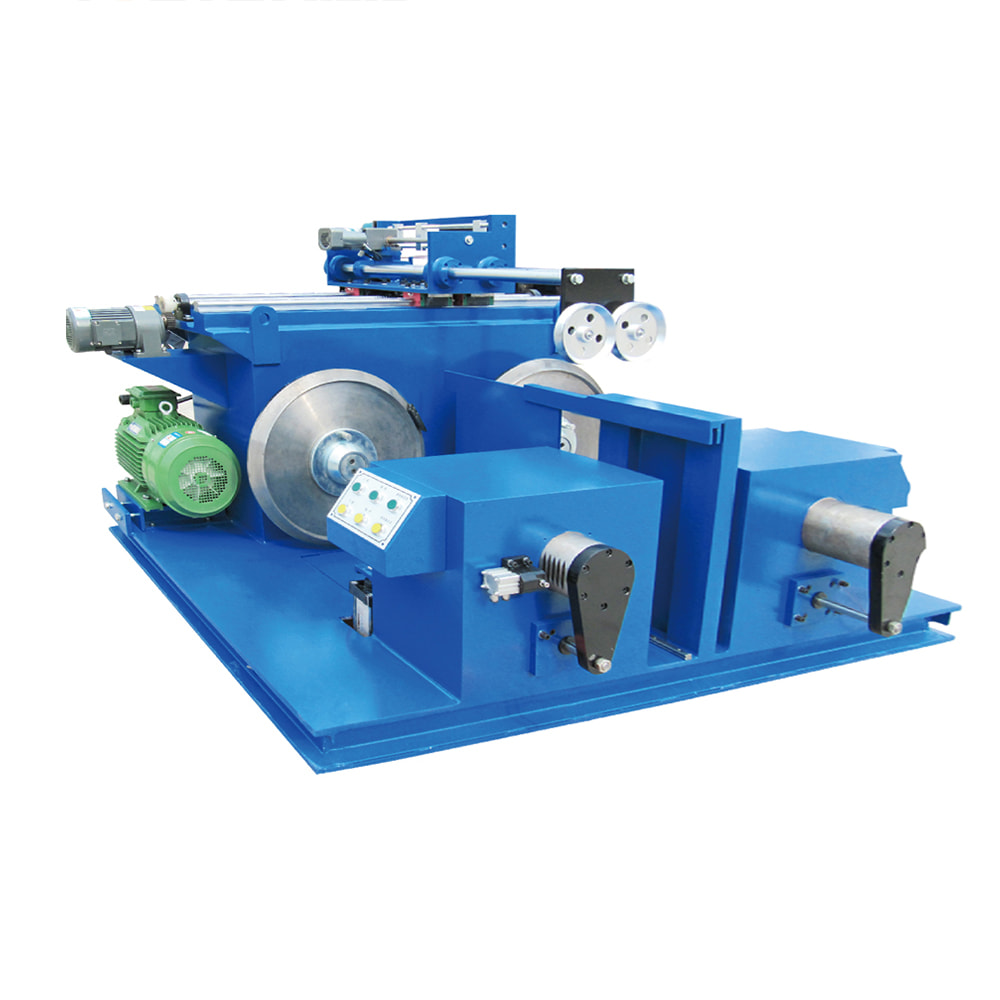

Brass Wire Drawing Machines are at the core of many industries, providing the essential process of transforming raw brass into high-precision wire used across a wide range of applications. However, the needs of different industries can vary greatly, which is why the ability to customize these machines is so important. Customization allows manufacturers to tailor the machine to meet the unique demands of specific sectors, ensuring optimal performance and product quality. Whether it’s for electronics, automotive, or jewelry, the flexibility of Brass Wire Drawing Machines can make all the difference in achieving the desired results.

The electronics industry, for example, demands extremely fine, precise brass wire for use in connectors, circuit boards, and other critical components. Brass wire used in electronics must have a consistent diameter, smooth surface, and the ability to conduct electricity effectively. A Brass Wire Drawing Machine designed for this industry can be customized to draw very thin wires, often as thin as a few microns, with a high degree of accuracy. By adjusting the machine's parameters, such as tension control, wire speed, and die configuration, manufacturers can ensure the wire meets the stringent specifications required for electronic applications.

In the automotive sector, brass wire is commonly used in connectors, battery terminals, and other electrical components. The demands here are slightly different, with a focus on wire durability and resistance to environmental factors such as heat, vibration, and corrosion. For this purpose, Brass Wire Drawing Machines can be customized with features that enhance the wire’s toughness and longevity. For instance, machine settings can be adjusted to create a wire that is slightly thicker and more robust, offering increased performance in harsh automotive environments. The ability to fine-tune the drawing process ensures the wire meets industry standards while providing optimal functionality.

For the jewelry industry, brass wire is used in a variety of applications, from creating delicate chains to more intricate designs. The key focus here is on aesthetics, as well as precision. Brass Wire Drawing Machines can be customized to produce wire with the right balance of smoothness and flexibility, which is crucial for jewelry manufacturers. Custom dies and tension systems can be incorporated to achieve the exact wire finish required for different jewelry styles, ensuring a high-quality product that is both functional and visually appealing. Customization also enables the machine to produce varying wire diameters that suit different types of jewelry designs, allowing manufacturers to stay competitive in the ever-evolving market.

Customization isn’t limited to wire dimensions alone; the surface finish is just as important. In many industries, including medical devices and electronics, the surface finish of the brass wire is a crucial factor. For these applications, Brass Wire Drawing Machines can be equipped with systems that ensure a smooth, polished finish, free from defects that could compromise the product’s performance. These custom features allow manufacturers to meet the high standards set by industries that require flawless wire surfaces to ensure product quality and reliability.

In addition to size and surface finish, the material properties of the wire itself can be tailored using a customized Brass Wire Drawing Machine. For example, the machine can be adjusted to control the hardness of the brass wire, which is especially important for applications where the wire needs to maintain strength without being brittle. This level of control ensures that the final product performs as expected in its intended application, whether that be in highly sensitive electrical components or robust automotive parts. By offering such customization, manufacturers can produce brass wire that meets the exact specifications required by different industries.

Finally, the ability to customize Brass Wire Drawing Machines also extends to operational features that improve efficiency and productivity. For industries with high-volume production needs, machines can be adjusted to handle faster speeds or integrate automatic systems for reducing downtime. By incorporating advanced automation systems, these machines can optimize the wire drawing process, improve overall output, and reduce the need for manual intervention. This customization not only enhances productivity but also contributes to a smoother workflow, allowing manufacturers to meet tight deadlines and high production demands.

In conclusion, the customization options available for Brass Wire Drawing Machines are invaluable for industries that rely on brass wire for their operations. From electronics and automotive to jewelry and beyond, the ability to tailor the machine to meet the specific needs of each sector ensures the production of high-quality wire with precise dimensions, durability, and surface finishes. As industries continue to evolve and demand more specialized products, the customization capabilities of Brass Wire Drawing Machines will play a critical role in staying ahead of the competition and ensuring product excellence.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us