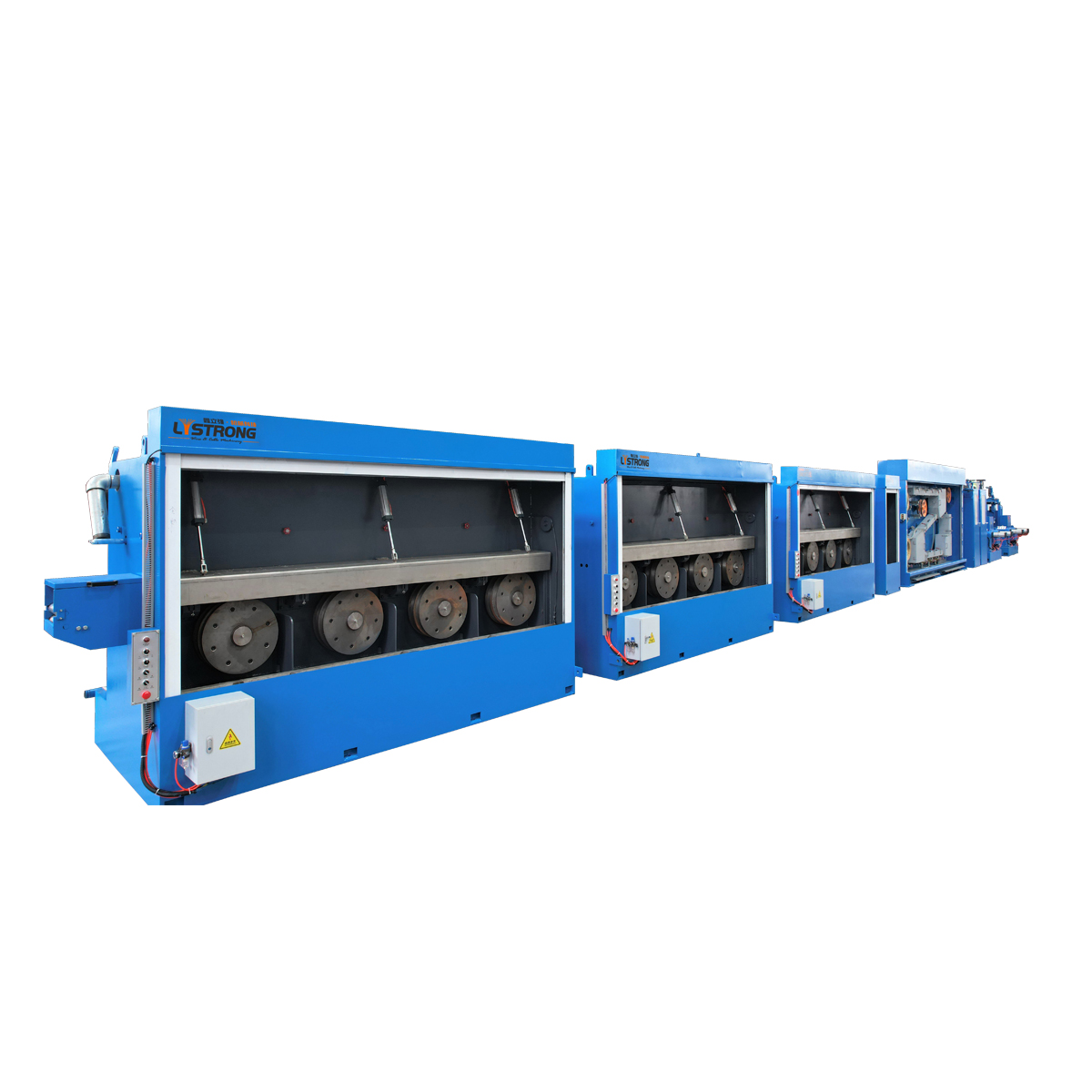

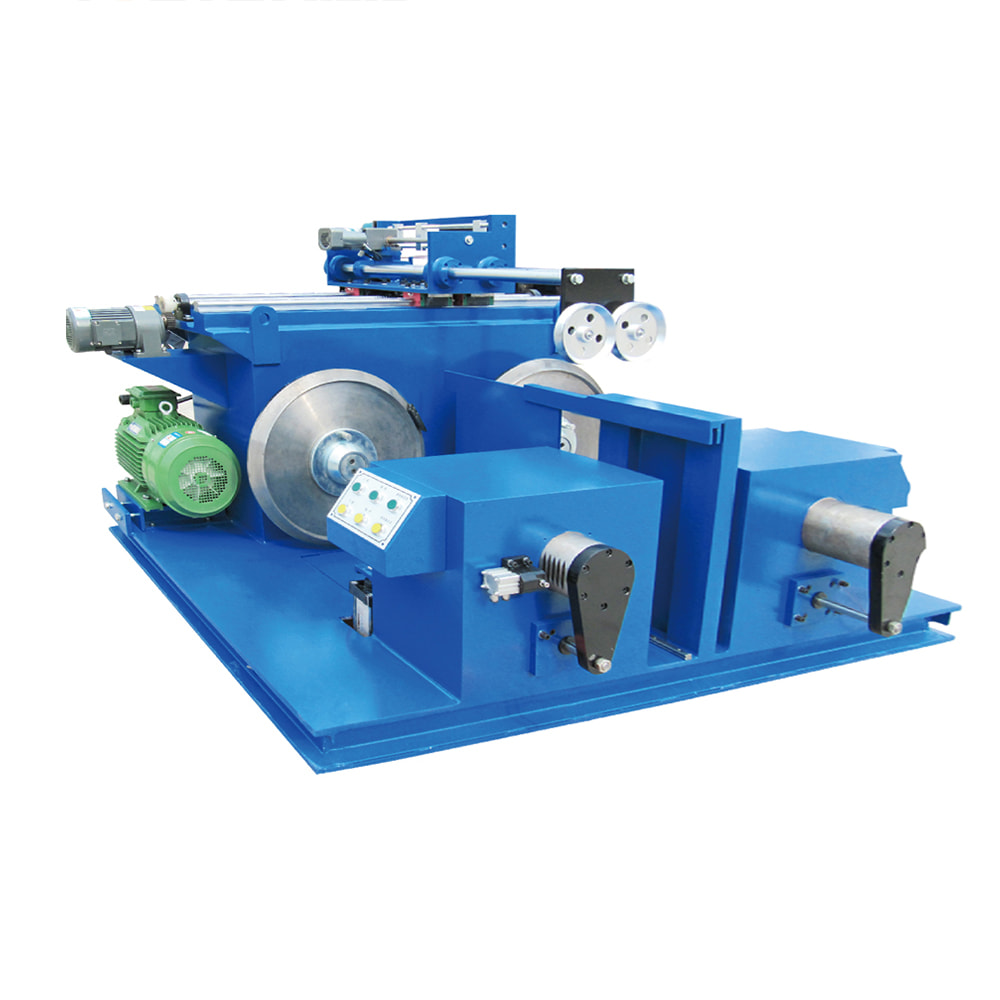

In the manufacturing of aluminum wire, precision and stability are essential throughout the wire drawing process. Among the critical components of Aluminum Wire Rod Breakdown Machines, the transmission system directly influences the machine’s efficiency, operational noise, and maintenance needs. While various drive types exist, belt transmission continues to be a preferred solution for horizontal-type breakdown machines. Its mechanical simplicity and functional reliability make it especially suitable for the high-speed, continuous operation demanded in modern aluminum wire production lines.

Belt-driven systems offer a smoother power transfer compared to rigid gear transmission. This helps to reduce shock loads and mechanical vibration during drawing, which translates to more stable die performance and consistent tension on the aluminum wire. Especially when working with aluminum rods starting from 9.5mm and reducing them to as fine as 1.5mm in diameter, such mechanical stability becomes a decisive factor in achieving uniform product quality. In breakdown machines designed for this process, even minor fluctuations in torque can influence wire dimensions, coiling behavior, and downstream compatibility.

Another major advantage of belt transmission in rod breakdown machines is the reduced noise level during operation. Compared to gear-based or chain-driven alternatives, belts run quieter and contribute to a more comfortable working environment on the factory floor. This might seem like a minor benefit at first glance, but for facilities running multiple Aluminum Wire Rod Breakdown Machines in parallel, the cumulative reduction in sound pollution improves both operator comfort and long-term machine monitoring clarity.

From a maintenance standpoint, belt systems are also easier and less costly to service. Replacement procedures are straightforward, and visual inspections quickly reveal wear, misalignment, or slippage. This allows operators to schedule preventative maintenance with minimal machine downtime. Moreover, belt drives inherently have fewer lubrication points and generate less frictional heat, which not only contributes to machine longevity but also supports energy efficiency goals—an increasingly important consideration for manufacturers focused on operational cost control and sustainability metrics.

In terms of alignment flexibility, belt transmission provides more tolerance than gearboxes, which require extremely precise meshing to function correctly. Aluminum wire drawing often involves complex multi-pass setups, and minor shifts in pulley positioning won’t disrupt the belt drive's function, whereas a rigid system would risk jamming or excessive wear. This added flexibility proves especially valuable when machines are subjected to variable loads, or when integrating them into existing production lines with tight layout constraints.

It's also worth noting that the use of belt transmission helps to protect more expensive components of the Aluminum Wire Rod Breakdown Machine. In the event of an overload or sudden stop, the belt can absorb part of the shock and reduce the risk of motor or gearbox damage. For operations dealing with different aluminum wire specifications and frequent adjustments, this built-in resilience can help avoid costly repairs or unplanned production halts.

When evaluating rod breakdown equipment, many buyers focus primarily on drawing capacity or coiling technology. However, as experienced manufacturers, we always advise our customers not to overlook the transmission system design. The belt-driven configuration in our aluminum rod breakdown machines is not just a feature—it’s a well-considered decision grounded in years of operational data and feedback from real industrial environments. It reflects our commitment to building equipment that balances performance, reliability, and ease of maintenance.

Ultimately, a well-designed belt transmission system enhances the total lifecycle value of the machine. For customers seeking a dependable solution that performs under pressure without demanding constant upkeep, our Aluminum Wire Rod Breakdown Machines deliver a finely tuned balance of mechanical innovation and user-friendly design.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us