Introduction

In modern manufacturing, efficiency, precision, and automation are key to maintaining competitiveness. One of the critical innovations in wire and cable processing is the Automatic Wire Take Up Machine. Designed to wind wire, cable, and other elongated materials onto spools, reels, or coils, these machines are essential in industries ranging from electronics and automotive to telecommunications and heavy machinery. By automating the take-up process, manufacturers reduce labor costs, minimize waste, and achieve higher consistency.

What is an Automatic Wire Take Up Machine?

An Automatic Wire Take Up Machine is an advanced piece of equipment that continuously winds wire or cable onto reels or spools at controlled speeds and tension. Unlike manual or semi-automatic winding systems, these machines use programmable logic controllers (PLCs), servo motors, and precision sensors to optimize the winding process without human intervention.

Key Components:

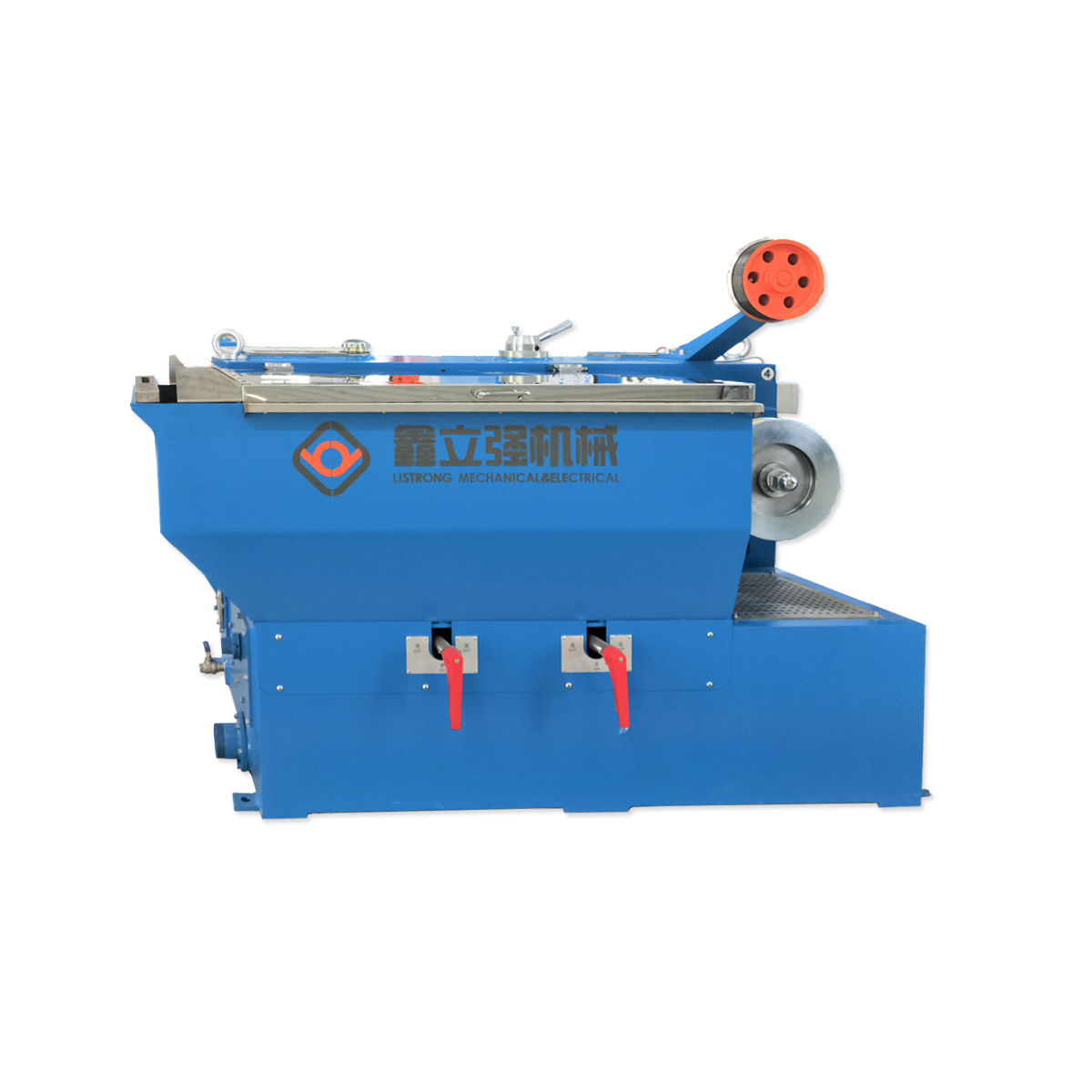

Pay-off unit – Feeds the wire or cable from production lines.

Tension control system – Ensures consistent wire tension to prevent breakage or slack.

Traverse mechanism – Guides the wire evenly across the reel width.

Reel holding system – Automatically loads and unloads reels or spools.

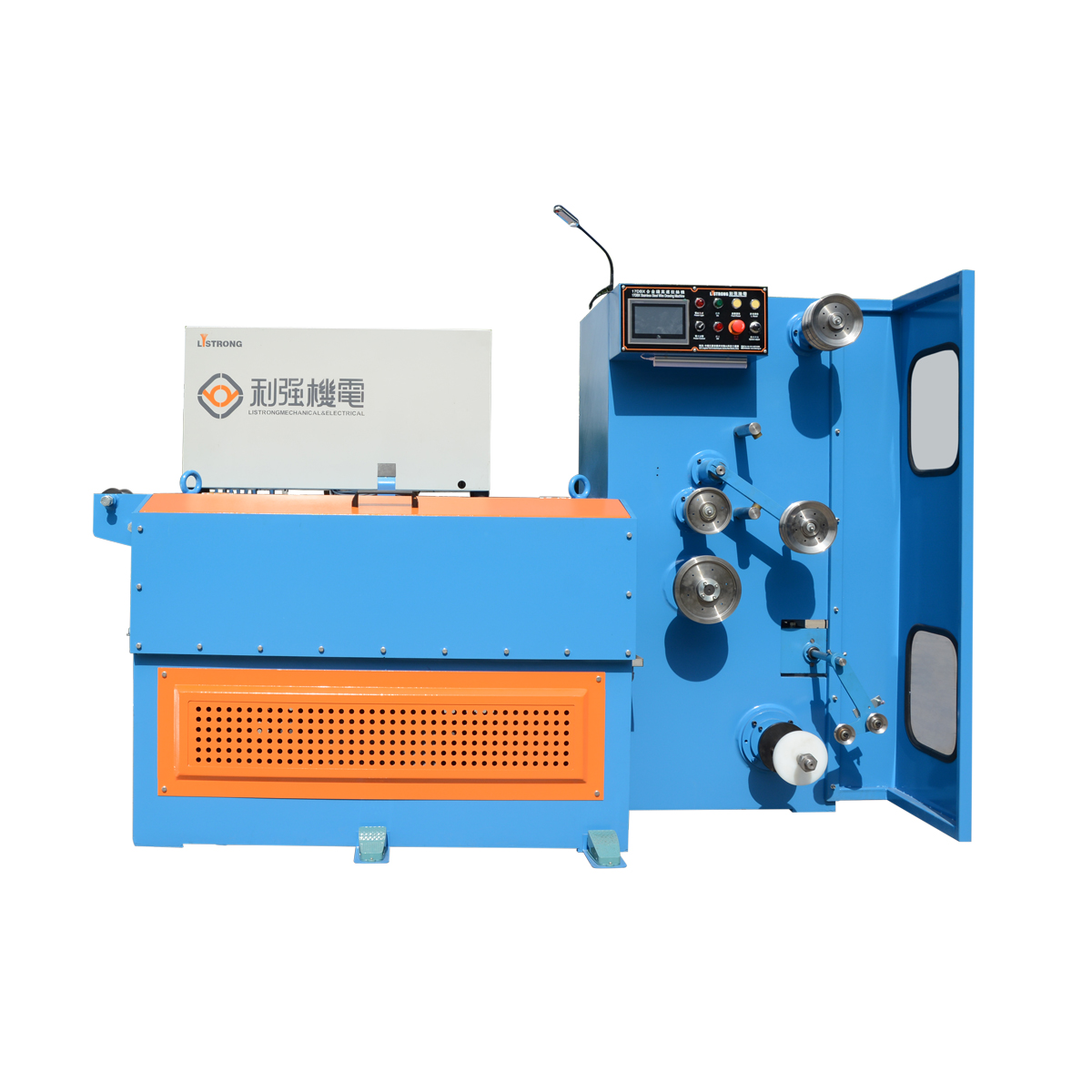

Control panel (PLC or HMI) – Allows operators to set parameters such as length, speed, tension, and winding pattern.

Safety systems – Emergency stops, overload protection, and sensors to prevent accidents.

How It Works

Feeding – Wire is guided into the machine from the production line.

Tension Regulation – Sensors and braking systems maintain optimal tension.

Traverse Motion – The wire is distributed evenly across the spool through synchronized linear guides.

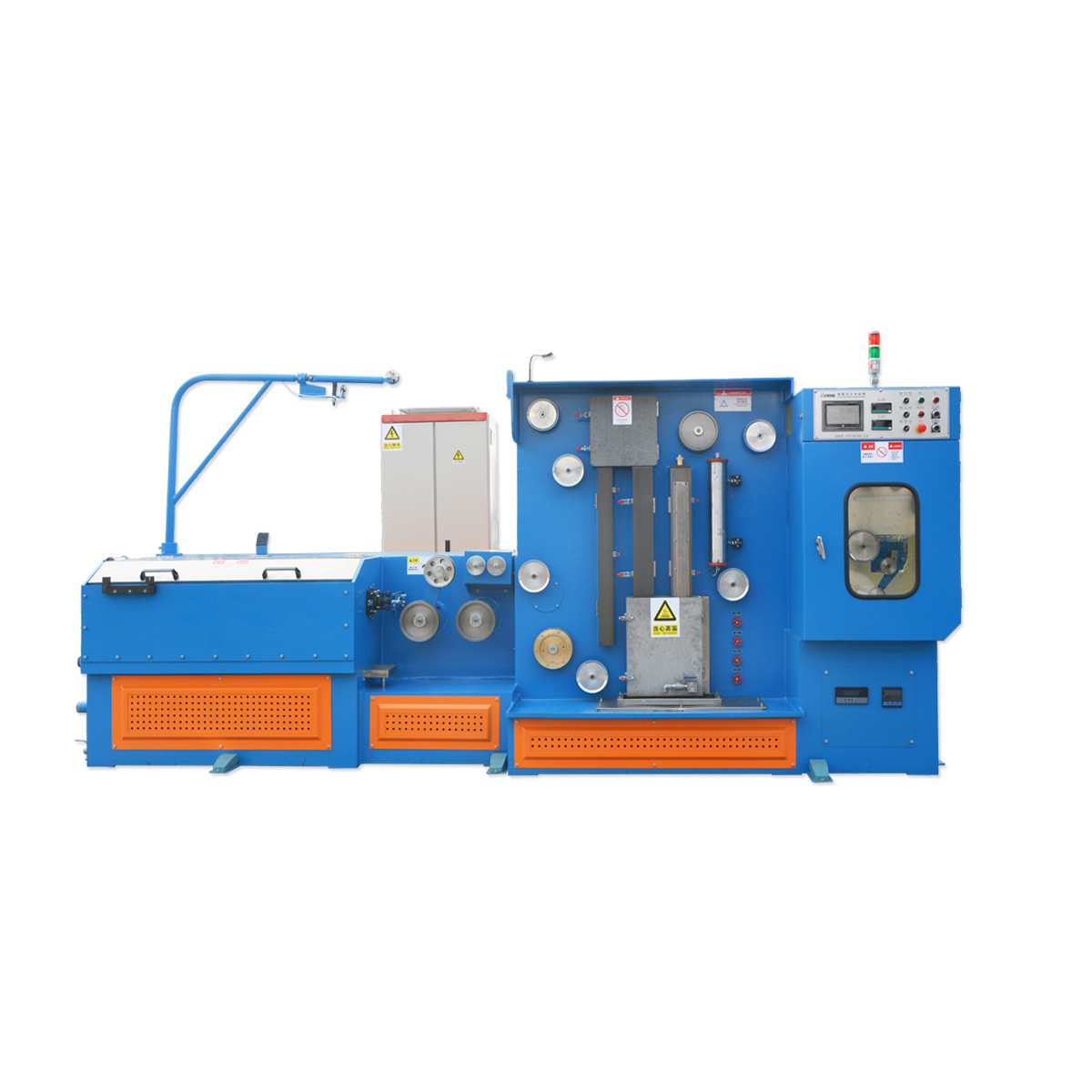

Reel Changeover – At completion, the machine automatically stops, cuts the wire (optional), and switches to a new reel.

Finished Product – Neatly wound reels are ready for packaging, shipping, or further processing.

Types of Automatic Wire Take Up Machines

Automatic take-up machines come in different configurations depending on application requirements:

Single-Spool Take Up Machines

Designed for smaller-scale operations.

Manual reel change required but winding is automatic.

Dual-Spool (or Auto Changeover) Take Up Machines

Allows continuous operation.

When one reel is full, the machine automatically switches to a new reel without halting production.

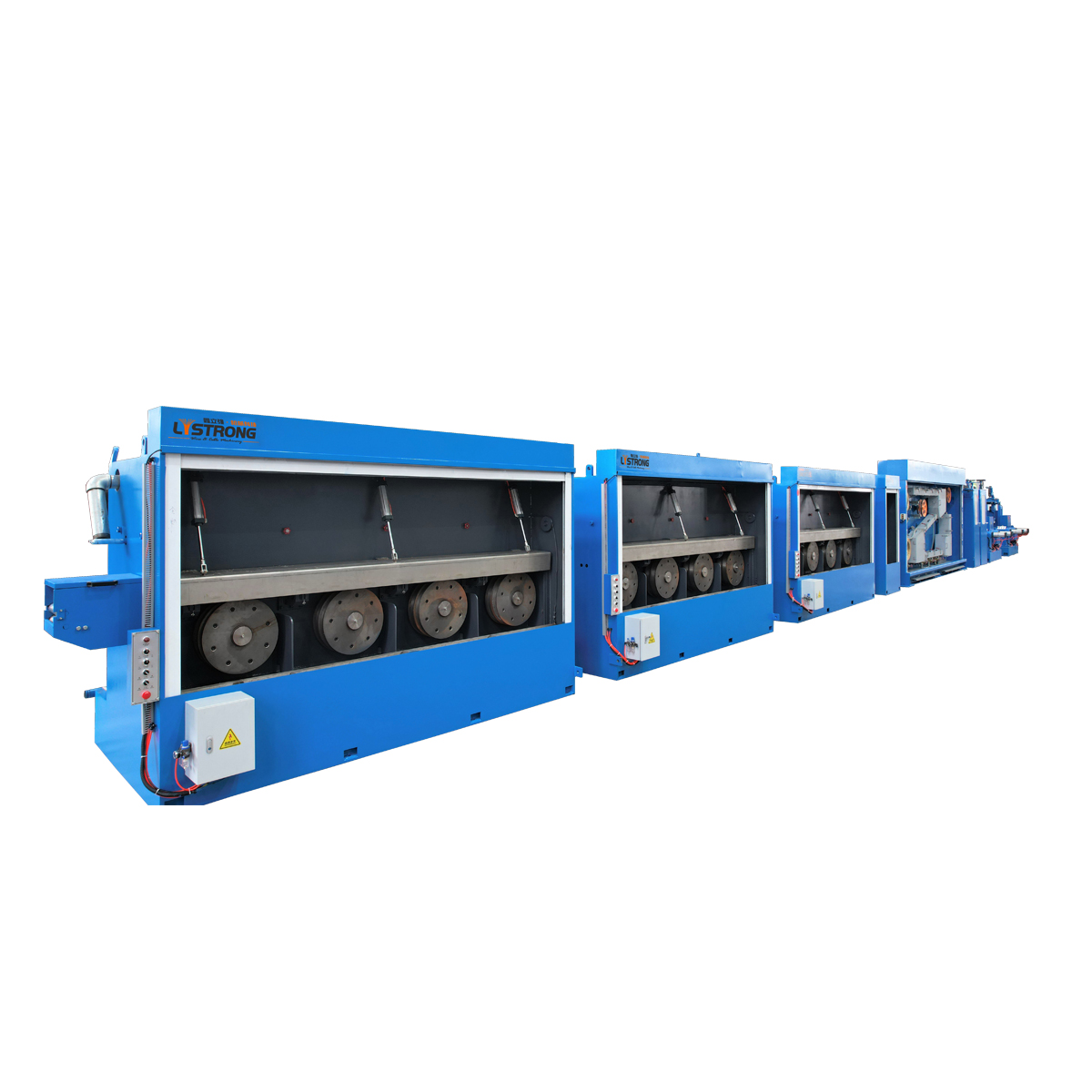

Heavy-Duty Industrial Take Up Machines

For large-diameter power cables, steel wires, or industrial ropes.

Equipped with hydraulic lifting systems to handle heavy reels.

High-Speed Precision Take Up Machines

Used in fine wire and fiber optic cable industries.

Prioritize speed, accuracy, and gentle handling of delicate materials.

Benefits of Automatic Wire Take Up Machines

Increased Efficiency – Continuous, automated winding reduces downtime and labor costs.

Consistency & Quality – Uniform winding prevents tangling, overlapping, or uneven spooling.

Reduced Waste – Precise tension control minimizes breakage.

Labor Savings – One operator can supervise multiple machines.

Safety Improvements – Automation reduces manual handling of heavy reels.

Scalability – Machines can be integrated with upstream production lines, enabling fully automated manufacturing systems.

Industrial Applications

Automatic Wire Take Up Machines are indispensable in a variety of industries:

Electrical Cable Manufacturing – Power cables, communication cables, and control cables.

Automotive Industry – Wiring harness production for vehicles.

Telecommunications – Fiber optic and data cable winding.

Metal Industry – Steel wires, copper wires, and aluminum conductors.

Textile & Rope Manufacturing – Synthetic fibers, ropes, and specialty cords.

Technology Trends in Wire Take Up Systems

Recent innovations are shaping the future of these machines:

Smart Automation – Integration with IoT and Industry 4.0 for remote monitoring and predictive maintenance.

Energy Efficiency – Use of regenerative drives and optimized motors.

Adaptive Tension Systems – AI-controlled tension adjustment for varying wire thicknesses.

Modular Designs – Machines that can adapt to different reel sizes and product types.

Challenges and Considerations

While automatic take up machines offer many advantages, manufacturers must address key challenges:

Initial Investment Cost – High-tech systems can be expensive for small producers.

Maintenance Needs – Sensors, motors, and PLCs require periodic calibration and servicing.

Customization – Different wire types and industries demand tailored solutions.

Training Requirements – Operators must be skilled in handling automated systems.

Future Outlook

The global demand for automatic wire take up machines is expected to grow steadily, fueled by the rapid expansion of electric vehicles, renewable energy infrastructure, and 5G networks. As technology evolves, these machines will become smarter, more energy-efficient, and more versatile, further cementing their role in modern manufacturing.

Conclusion

The Automatic Wire Take Up Machine is more than just a convenience—it is a necessity for industries that value precision, efficiency, and reliability. By automating what was once a labor-intensive process, these machines have transformed wire and cable manufacturing, enabling companies to scale operations, reduce costs, and deliver consistent quality. As automation technology continues to evolve, wire take up machines will remain at the forefront of industrial progress.

中文简体

中文简体 русский

русский Español

Español عربى

عربى

Contact Us